Ford Flathead V8 Engine Guide

Meet Austin

Austin has been a muscle car enthusiast since an early age with his Dad having a collection including a 1965 Mustang, 1968 Mercury Cougar, and a 1969 Mustang Mach 1 among many others. Austin received a technical writing degree from University of Colorado Denver with the intentions of becoming an automotive journalist. His automotive knowledge, enthusiasm, and hands on experience allow him to craft detailed, accurate, and high-quality articles for the passionate Muscle Car Club audience.

Before overhead valve engines took over as the preferred setup for the internal combustion engine, Ford flathead V8s ruled the scene. It is a common misconception that the Ford flathead V8 was the first V8 engine. In fact, that honor goes to the Antoinette V8, invented in 1904 by Leon Levavasseur. Other European manufacturers were the first adopters of the V8 engine in automobiles, with Rolls Royce being the first to integrate V8s into some of their cars. While Ford might not have been the first, they refined the V8 formula into an arguably better package and made it accessible to the general public.

Over its production period between 1932 and 1953, the Ford flathead V8 received multiple revisions, ultimately leading to an array of different displacements and configurations. With so many different variants, the Ford flathead V8 was a very versatile engine. Smaller displacement variants fit comfortably in cars like the Ford Model 18, while larger displacement variants were used in larger F7 and F8 Ford trucks.

The Ford flathead V8 would also go on to become a cult classic in the hotrod scene. In fact, it essentially introduced the hot rodding scene to the world. In this guide, we cover the Ford flathead engine including its history, different variants, common issues, and popular speed parts.

Ford Flathead V8 Engine History

Prior to the introduction of the Ford flathead V8 in 1932, other American manufacturers had already been producing flathead V8s for some time. Cadillac, for example, sold flathead-powered vehicles as early as 1914. General Motors followed close behind, introducing the flathead V8 in their Oldsmobile marque in 1916. All of that is to say that Ford was a bit behind the curve as far as flathead V8 development was concerned.

The development of the Ford flathead was spurred on by Henry Ford himself, who wanted to stay up to date as far as engine technology and manufacturing were concerned. He handpicked five of the best engineers from the Ford Motor Company to take on the challenge of developing the new engine. Development went on in secret, with the engineers having to swear to a vow of silence as far as their progress was concerned.

Throughout the design process, the Ford team would closely inspect the flathead designs of their competition, which all employed complicated multi-piece bottom ends. Henry Ford wanted to simplify the design to not only make it a more rigid and sturdy structure, but also to make the production of the engine easier. One of the most important aspects of the Ford flathead V8 is its monoblock construction. Prior to the flathead V8, Ford had been able to produce engines with one-piece casting, with the crankcase and block cast together. That is a design philosophy that carried over to the flathead V8.

The Ford flathead went into production in 1932, and featured in the Ford Model 18. The Model 18 would eventually become known as the Ford V-8 due to its unique engine. The Ford flathead V8 was initially only offered in a single displacement, 221 cid. It wouldn’t be until 1937 before Ford introduced the 136 flathead.

What is a Flathead V8?

Many enthusiasts have heard of flathead engines but don’t know what they are exactly. Flathead engines are simple machines, at least as far as engines go. Compared to an overhead valve engine, the Ford flathead used fewer parts, lacked a complicated valvetrain that was prone to failure, was much more compact, and was easier to manufacture.

The flathead V8 got its name from the structure of the cylinder heads. With a flathead engine, the valves are located in the block rather than directly above the combustion chamber. This means that the cylinder heads can be essentially flat as a board. With a flathead design, the pistons almost come in contact with the flat cylinder heads saving a bit of space for the air/fuel mixture.

Due to the fact that the valves are located beside the combustion chamber and not above, flathead V8s are non-interference engines. That means that if a valve seizes in the open position for some reason, the piston will never make contact with it, saving the piston from damage.

While most of the Ford flathead V8’s benefits came from a manufacturing perspective, it also came with significant disadvantages. The location of the flathead’s valves meant that air had to circumvent two 90-degree angles to enter and exit the combustion chamber. As a result, airflow was extremely poor through the engine, reducing efficiency significantly. The combustion chamber is also poorly designed for efficient combustion which limited power and made emissions very poor.

Ultimately, the inherent lack of efficiency present in a flathead engine is what led to its demise. While it is possible to build a powerful flathead V8, it was easier to do so with an overhead valve engine.

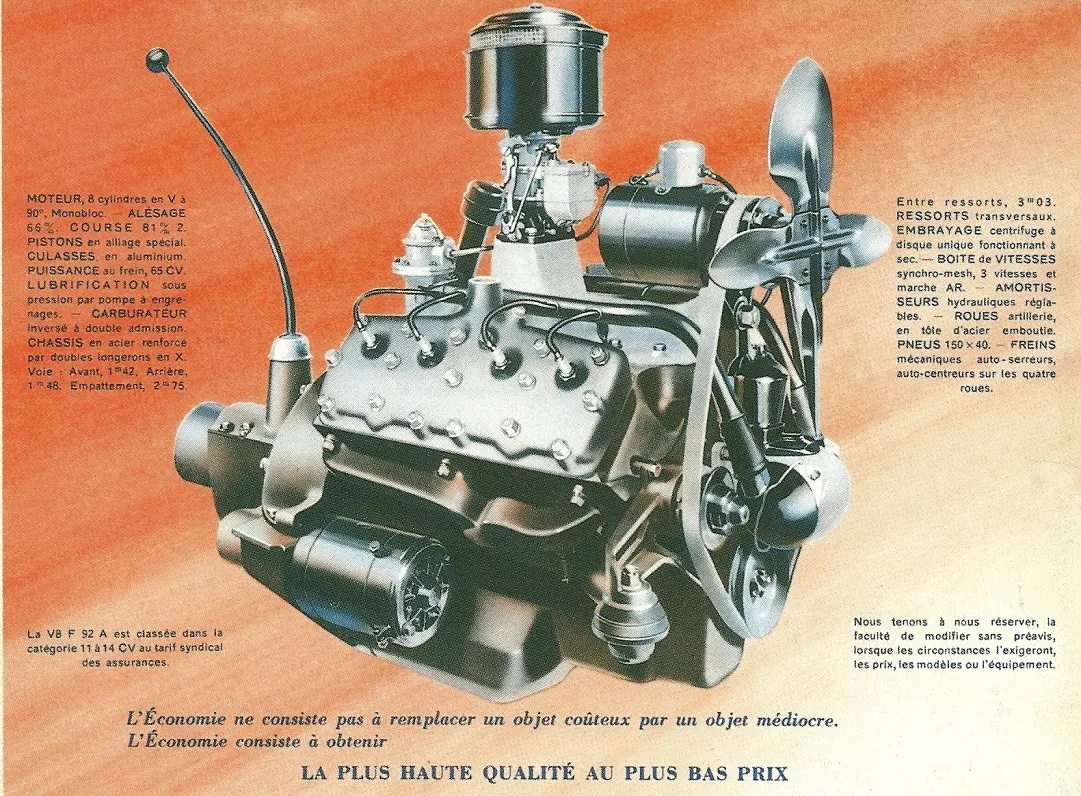

Ford Flathead V8 – 221 / Ford 85 Horse

The initial Ford Flathead was introduced to the world in 1932 in the Ford Model 18/Ford V-8. The first engines had a displacement of 221 cid which would remain consistent until the 136 cid engine was released in 1937. Throughout the 221 V8’s build cycle, its compression was raised multiple times between 1932 and 1936. The 221 V8’s compression was raised to 6.33:1 for 1933 and 1934, raising horsepower significantly. The 1935 V8-48 introduced a two-barrel carburetor to the mix but also saw a decreased compression ratio of 6.3:1. Despite the lesser ratio, the V8-48 flathead saw a 10 horsepower increase over the previous model.

Many of the early 221 flatheads suffered from extreme overheating issues caused in part by the location fo the water pump. Prior to 1937, the 221 flathead V8’s water pump was located on the front of the cylinder heads. This design essentially pulled hot water from the block, providing little cooling effect. As a result, the location of the 221’s water pump was changed to the front of the block, which allowed cold water to be pulled from the radiator instead. Post-1937 221 flatheads saw a horsepower increase to 85 and 94 horsepower depending on the cylinder head that was installed.

Ford Flathead Engine Specs – 221

| Year | Displacement | Bore | Stroke | Compression Ratio | Horsepower | Torque | Model |

| 1932 | 221 CID | 3.0625 | 3.75 | 5.5:1 | 65 Horsepower | 18 | |

| 1933 | 221 CID | 3.0625 | 3.75 | 6.33:1 | 75 Horsepower | 40 | |

| 1934 | 221 CID | 3.0625 | 3.75 | 6.33:1 | 85 Horsepower | 40A | |

| 1935 | 221 CID | 3.0625 | 3.75 | 6.33:1 | 85 Horsepower | 38 | |

| 1936 | 221 CID | 3.0625 | 3.75 | 6.33:1 | 85 Horsepower | 68A | |

| 1937 | 221 CID | 3.0625 | 3.75 | 6.2:1 / 7.5:1 | 85/95 HP | 78 | |

| 1938-1942 | 221 CID | 3.0625 | 3.75 | 6.12:1 – 6.2:1 | 85-90 HP |

Ford Flathead – 136

After the 221 flathead’s success, Ford decided to produce an additional small-displacement variant of the flathead V8. In contrast to the larger 221 V8, the 136 flathead had a displacement of 136 cid and only produced 60 horsepower initially. This variant was not popular in the American market, as the 221 V8 produced a more promising 85 horsepower.

The V8-60, as it would be called, provided significantly better fuel economy than the larger 221 V8 which was meant to compensate for a lack of V6 options in the Ford catalog. Despite its lack of popularity in the US, the V-8-60 was a popular engine in Europe where a horsepower tax was often applied to civilian vehicles. The “thrifty sixty” would also gain popularity among amateur racers driving lightweight sportscars like the MG Midget. The 136 cid V8 was eventually discontinued in the US in 1940. It was ultimately succeeded by the 226 straight-6.

Ford Flathead Engine Specs – 136

| Year | Displacement | Bore | Stroke | Compression Ratio | Horsepower | Torque | Model |

| 1937 | 136 CID | 2.6 | 3.2 | 60 Horsepower | 74 | ||

| 1938 | 136 CID | 2.6 | 3.2 | 60 Horsepower | 82A | ||

| 1940 | 136 CID | 2.6 | 3.2 | 60 Horsepower | 022A |

Ford Flathead – 239

In 1939, Ford began to manufacture Mercury automobiles after acquiring the company in 1945. Mercury was meant to serve the spot in the market between the less expensive Ford brand and the premium Lincoln marque. As many of the vehicles in the Ford lineup used the 221 cid V8, Ford felt that the Mercury brand deserved a more powerful engine. As a result, the 239 V8 was created.

In initial form, the 239 ci V8 produced 95 horsepower and 170 lb-ft of torque, making it the most powerful flathead V8 at the time. By 1942, the V8-29A 238 flathead V8 received a compression bump to 6.4:1 and horsepower subsequently rose to 100 horsepower. Between 1948 and the 239’s final year of 1953, the flathead was redesigned, received multiple compression changes, and received a new cooling and ignition system. In its final form, the 239 V8, renamed the V8-B3 and 8RT in truck applications, produced 110 and 106 horsepower respectively.

Ford Flathead Specs – 239

| Year | Displacement | Bore | Stroke | Compression Ratio | Horsepower | Torque | Model |

| 1939 | 239.4 CID | 3.1875 | 3.75 | 6.3:1 | 95 Horsepower | 99A | |

| 1940 | 239.4 CID | 3.1875 | 3.75 | 6.3:1 | 95 Horsepower | 09A | |

| 1941 | 239.4 CID | 3.1875 | 3.75 | 6.3:1 | 95 Horsepower | 19A | |

| 1942 | 239.4 CID | 3.1875 | 3.75 | 6.4:1 | 100 Horsepower | 29A | |

| 1946 | 239.4 CID | 3.1875 | 3.75 | 6.8:1 | 100 Horsepower | 69AFord | |

| 1947-1953 | 239.4 CID | 3.1875 | 3.75 | 6.8:1 | 100-110 |

Ford Flathead – 255

In 1948, the Ford 239 flathead V8 was given a 4-inch-stroke crank which increased displacement to 255 cid. Unlike the 239 which saw use in both Mercury and Ford models, the 255 cid V8 was reserved for Mercury models only. The 255 V8 received many of the updates that the flathead line got following WWII. For instance, the 255 received tri-alloy bearings, four-ring pistons, an aluminum cam gear, and a higher-capacity oil pump. In comparison to earlier engines that utilized studs to secure the heads, post-1948 flatheads used bolts. Higher octane was also available at the time, meaning that compression could be safely increased to 6.8:1.

Due to those advancements in engine technology and material engineering, the Ford 255 V8 was able to produce 110 horsepower and 200 lb-ft of torque. There was little change in the engine between 1948 and 1951, with the biggest change taking place in 1952. Compression was raised to 7.2:1 for the V8-MA which resulted in a horsepower boost to 125 horsepower. Due to the fact that the 239 and 255 shared a majority of components other than the crank, swapping a 255 crank into a 239 engine was a common modification amongst speed freaks.

Ford Flathead Engine Specs – 255

| Year | Displacement | Bore | Stroke | Compression Ratio | Horsepower | Torque | Model |

| 1949 | 255 CID | 3.5 | 3.4 | 6.8:1 | 112 Horsepower | CM | |

| 1950-1951 | 255 CID | 3.5 | 3.4 | 6.8:1 | 112 Horsepower | CM | |

| 1952-1953 | 255 CID | 3.5 | 3.4 | 6.8:1 | 125 Horsepower | CM |

Ford Flathead V8 – 337

The final iteration of the Ford flathead V8 came in the form of a 337 cid V8. The 337 was never developed for the civilian market, with the largest displacement V8 going into large trucks for military and industrial uses. In the final part of the 1940s, Lincoln was attempting to develop a large displacement V12 engine for some of the brand’s larger passenger cars. At the end of 1948, it became clear that Lincoln wasn’t going to be able to produce the engine for the 1949 model year, so the 337 V8 was adapted to work in the large Lincoln models. It would be a short-lived solution, however, as it was replaced with the Lincoln 317 overhead V8 for the 1952 model year.

Ford Flathead Engine Specs – 337

| Year | Displacement | Bore | Stroke | Compression Ratio | Horsepower | Torque | Model |

| 1948 | 337 CID | 3.5 | 4.38 | 6.8:1 | 145 Horsepower | ||

| 1949 | 337 CID | 3.5 | 4.38 | 152 Horsepower | |||

| 1950-1953 | 337 CID | 3.5 | 4.38 | 152 Horsepower |

Ford Flathead V8 Issues and Fixes

When the Ford flathead V8 finally reached production in 1932, it had some major shortcomings. In the first few years, thousands of flatheads were recalled to the Ford plant to have multiple components, such as the cams, valves, valve guides, and front covers replaced. While that seems like a lot of engines, in reality, that was only a small percentage of the 212,238 flathead engines that Ford produced between March and December of 1932.

Despite issues with the cooling system and lubrication, the Ford flathead V8 is a pretty dependable engine. The flathead V8’s simplicity certainly works in its favor on this front. However, due to the engine’s age at this point, they are obviously more prone to failure than other modern engines. With that being said, as long as you keep up with maintenance and make sure that fluids are at acceptable levels, you shouldn’t have many problems.

Ford Flathead Overheating

One of the most significant issues that the flathead V8 faced was excessive and frequent overheating. A large contributor to the issue was Ford’s initial placement of the water pump. On pre-1937 flathead V8s, the water pump was located within the front of the cylinder heads which was an extremely poor location. Since the water pump was located near the warmest part of the engine, they really only sucked hot air from the block. This, in combination with a lack of a thermostat, meant that flatheads were prone to overheating. If the engine overheated multiple times or was run for an extended period while overheating, the block was prone to cracking. Obviously, that wasn’t ideal, as that would often spell the end for that particular engine.

To fix the issue, the thermostat location was changed on Ford flatheads after 1937. Instead of mounting the water pump in the cylinder head, it was moved to the front of the block. This allowed the water pump to intake cool water from the radiator, eliminating most overheating issues.

Ford V8 Lubrication Issues

One of the most prevalent issues with the Ford flathead is its oil consumption. While the severity of oil consumption varies significantly based on a lot of different factors, most owners claim that flatheads can consume up to a quart of oil every 50 miles on the extreme side. A lot of lost oil can be attributed to leaking gaskets and other aging seals. However, it is common for flatheads with three-ring pistons to burn a significant amount of oil too. The most common solution to that issue is to install four-ring pistons.

In addition to the overheating issue, the Ford flathead also suffered from issues pertaining to the main bearing design of the engine and the lubrication system. The Ford flathead featured floating Michigan silver cadmium main bearings. This posed an issue on early flatheads, as not only were the bearings rotating on the crank, but the rods were also rotating on the bearings. Ultimately, Ford issued a bulletin about the issue

How Much Power Can A Flathead V8 Handle?

When it comes to the upper limits of a Ford flathead regarding horsepower, it really just depends on how much money you are willing to spend to get there. The physical limit of a flathead Ford is really dictated by airflow limitations and the fact that they are three-bolt main rather than five-bolt main engines. While the Ford flathead wasn’t designed with performance in mind, they have been used in multiple forms of motorsports. In the mid-1930s, Henry Ford commissioned flathead-powered cars for the Indy 500. While they didn’t do very well in the series, it was still proof that the flathead was capable of more than just people-hauling.

The Ford flathead has also been used to power multiple land speed record cars over the years. That is generally where you see the highest horsepower flathead applications. The legacy of Ford flatheads at Boneville is still alive and well to this day, with an entire class dedicated to flathead V8 records. It isn’t uncommon to see heavily modified flathead V8s pushing 300 horsepower, over three times what they produced from the factory. However, the fastest flathead on Earth is a 700-horsepower supercharged monster built by Ron Main in California. It set the record for the Bonneville flathead class at 302.2 mph.

Best Ford Flathead V8 Speed Parts

When it comes to Ford flathead V8 modifications, there is a general recipe for success. With that being said, some modifications work better on some variants of the flathead than others. If you are planning on building out a Ford flathead for a hotrod application, it is important to consider which variant will work best for your application. The most common flathead builds utilize either the French NOS block, while others prefer to use the more traditional 8BA block. Both have benefits and shortcomings. The French flathead block is preferable due to its more modern casting, resilience to block cracking, thicker decks, and larger main bearing caps. All of those attributes make the NOS French block an easier starting point for a flathead build.

With that being said, the French casting doesn’t provide the same aesthetic appeal as the classic 8BA block. The 8BA is also around 30 pounds later than its French counterpart. Once you have decided on a good starting platform, you’ll have to decide on whether or not you want to keep the engine modifications period correct or use modern aftermarket parts.

Of course, with an engine that is so widely celebrated and has been around for as long as the Ford flathead V8, there are almost endless modifications for it. Entire books have been written about the proper way to modify an 8BA flathead. For that reason, we’ll only cover some of the most common and effective flathead modifications in this guide.

Our picks for the best Ford flathead V8 modifications include:

- Ported Ford flathead block

- Ford flathead crankshaft swap

- Ford flathead cylinder head swap

Ported Ford V8 Engine / Reverse Flow Flathead Engine

Since the flathead has such poor airflow in factory form, one of the most common modifications is porting the block. A ported flathead block will allow for a less asthmatic engine. Since the flathead features a unique exhaust port design that travels through the block to allow for a faster warmup, air has to contend with multiple bends and angles that limit efficiency. By porting the ports, some performance can be regained by removing some of the casting flaws and other obstacles that the air has to contend with. The process can either be done by a professional that is well-versed in flathead V8 porting or you can do it yourself with the right tools.

Reversing the flathead’s flow is another common modification on high-horsepower builds, although it is a very in-depth, expensive, and time-consuming process. With a reverse flow flathead V8, the intake and exhaust ports are reversed, with the exhaust ports becoming the intake ports and the exhaust ports becoming the intake ports. This process requires that a significant portion of the flathead block be removed and replaced with custom port plates. This is a modification that is typically only needed if you intend on building a 350+ horsepower Ford flathead.

Ford Flathead Crankshaft Replacement

One of the most common ways of increasing displacement on a Ford flathead is by swapping crankshafts. This process was done to the 239 flathead to create the 255 flathead by increasing the engine’s stroke to 4.” As a result, the 239’s displacement was increased by 16 cubic inches. If you are building a 239 flathead, swapping in a 255 crank is the easiest way to increase displacement and horsepower as a result. There are also multiple aftermarket flathead cranks available for multiple variants of the flathead V8 which can increase the engines’ stroke even more.

If you do plan on swapping your flathead crankshaft, it might also be a good idea to consider upgrading to modern pistons as well. Modern flat-top Mahle pistons are a common swap and offer better ring designs. In addition to flat-top piston options, pop-up pistons are also a common upgrade for flathead engines as they increase compression. While pop-up pistons will certainly yield more horsepower, you’ll need corresponding cylinder heads in conjunction with them. Swapping flathead pistons can solve some of the flathead’s oil-burning issues, as oil is most commonly lost through factory flathead piston rings.

Upgraded Flathead Cylinder Heads

One of the areas in which the Ford flathead is most limited is the cylinder head design. Of course, the flat cylinder head is where the V8 engine gets its name. However, the factory heads aren’t exactly optimized. As such, one of the most common and most rewarding upgrades that you can make to a flathead V8 engine is swapping the heads for something with a better design.

Ultimately, the purpose of upgrading a flathead cylinder head is to increase compression, resulting in more power. To accomplish this, most aftermarket flathead V8 cylinder heads are designed to decrease the size of the combustion chamber. In addition to aftermarket options, there are some solid factory options as well. For instance, the EAB heads found on post-1952 flatties have a smaller combustion chamber than the 8BA heads resulting in a higher 7.2:1 compression ratio.

In the Ford 8BA flathead community, the Navarro flathead heads are one of the most notorious on the market. Manufacturing flathead heads since the 1950s, Navarro is known for build quality and high flow figures. If money is no object, Navarro flathead heads are the way to go. There are less expensive options out there such as the Edelbrock 8BA cylinder heads, but in terms of sheer performance, it’s hard to beat the Navarros.

The Ford Flathead V8 Legacy

At this point, the Ford flathead’s legacy should be pretty apparent. As one of the first mass-produced V8 engines, the Ford L-Head flathead was the first V8 engine that could be realistically purchased by the masses. Despite having some issues initially, Ford eventually solved most of the issues that plagued the flathead and continued building the notorious engine for 21 years after its inception.

Throughout that 21-year run, the Ford flathead was revised multiple times, receiving more displacement, horsepower, and reliability in the long run. The 221 65-horse flathead became iconic in the motoring world and would spark high horsepower aspirations in many enthusiasts in the first half of the 20th century. Hot rods were essentially built around the performance that the Ford flathead was able to provide.

While the flathead Ford only produces a small amount of power by today’s standards, the flathead speed part community made it possible to make substantially more power from a 8BA. Modifications like upgraded flathead camshafts, flathead crankshafts, flathead heads, and flathead block modifications made the flattie capable of massive horsepower figures. While the flathead Ford eventually became antiquated by the rise of the overhead valve V8, it still lives on in the hearts of many due to its major impact on the history of high-horsepower motoring.

If you enjoyed this article and are looking for more Ford engine guides, check out our Best Ford Mustang Engines In History Guide!