What Is a Carburetor And How Do They Work?

Meet Austin

Austin has been a muscle car enthusiast since an early age with his Dad having a collection including a 1965 Mustang, 1968 Mercury Cougar, and a 1969 Mustang Mach 1 among many others. Austin received a technical writing degree from University of Colorado Denver with the intentions of becoming an automotive journalist. His automotive knowledge, enthusiasm, and hands on experience allow him to craft detailed, accurate, and high-quality articles for the passionate Muscle Car Club audience.

Before the advent of fuel injection, cars needed a way of receiving both air and fuel as a source of combustion. As many people know, that is, at the most basic level, how an engine operates. In modern times, internal combustion engines work differently. With fuel injection, an engine relies on fuel injectors, a fuel rail, and a fuel pump to spray fuel directly into the combustion chamber, where it is mixed with air coming in from the intake manifold and ignited by spark plugs. However, that was too sophisticated of a system in the early days of the automobile.

With that being said, a carburetor is still a very sophisticated and meticulously designed piece of machinery. Since carburetors were around far before the advent of portable computing, cars relied on analog methods of receiving fuel and air. Carburetors rely heavily on the Bernoulli principle to operate, meaning that they are at the mercy of pressure changes and are sensitive to changing climates. While fuel injection might be the superior system in terms of ease of use and reliability, carbureted engines served the muscle community, and nearly every other automobile before the early 1950s, well.

In this article, we’ll break down the basics of what a carburetor actually is. We’ll also discuss how carburetors work and the individual circuits used by a carburetor to function correctly.

Why Do Cars Need Carburetors?

While that question has some validity, the short answer is they don’t. Cars only needed carburetors due to the fact that no one had been able to figure out a more efficient way of combining air and fuel and delivering it to the combustion chamber of an engine. A lack of digital technology is truly what made the carburetor such a universal device between 1887 and the early 1970s. While mechanical fuel injection was around in the early 1950s, carburetors were still more efficient and cost-effective. In the 1980s computerized engine management systems arose and were able to adjust air-to-fuel ratio in real-time, making the job of a carburetor much more straightforward, reliable, and efficient.

With that being said, the carburetor played one of the most important roles in the engine bay for nearly a century. Engines combine multiple forms of operation. They function at a mechanical level, a chemical level, and, now, a digital level. Carburetors helped engines function on a chemical level. Since all internal combustion engines require, somewhat obviously, combustion to get a car moving under its own weight, an engine requires fuel, oxygen, and a spark to produce motion. A carburetor is a self-contained device that intakes air and mixes it with fuel which is then fed to the engine. We’ll dive deeper into the specifics of how carbs function in the next section.

For an engine to function correctly and operate at different speeds, the air-to-fuel mixture needs to be adjusted in real-time. With electronic fuel injection, the onboard computer works that out. However, carburetors rely on fluid dynamics to adjust the air-to-fuel ratio.

How Does a Carburetor Work?

Most car enthusiasts that have never dealt with classic American muscle, or most cars pre-1975 for that matter, aren’t familiar with how a carburetor actually operates. Modern fuel injection systems are pretty simple when you break down the individual components. A carburetor, on the other hand, is actually a very nuanced and meticulously designed component. In a time before computers were small enough to fit in a car’s glovebox, fuel and air needed to be supplied to the engine without digital assistance. A carburetor’s mechanical nature is what requires the system to be so intricate and complex.

While the word “carburetor” has come to represent the device as a whole, carburetors can vary a significant amount based on their application. Most low-performance engines, like those found on lawnmowers and chainsaws typically only use a single carburetor. Other high-performance vehicles make use of multiple carbs. While their design can vary, the primary principle at play remains the same. All carburetors rely on the venturi effect in order to function.

Carburetor Design

Before we jump into the intricacies, it is important to have a general idea of what a carburetor looks like. In their most basic form, carburetors are vertical “tubes” that constrict in the center and widen again towards the bottom. The central constricted section is called a venturi. As air enters into the top of a carburetor, called the air cleaner, as it filters air coming in from the engine bay, and into the venturi, the air’s velocity increases as it goes from an area of high pressure to an area of low pressure but increased speed. This is the Bernoulli principle at work. The air then slows once it exits the venturi. This attribute of airflow is called the venturi effect, which is the scientific principle that allows a carburetor to operate.

There is also a horizontal chamber connected to the constricted venturi section of the vertical “tube.” This is where fuel enters the equation. As air passes through the venturi and across the horizontal fuel inlet jet. The low-pressure area created inside the venturi sucks air and fuel into the vertical section. It then enters the valves where it is then introduced to the combustion chamber.

As we have already discussed, there needs to be a way of controlling the air-fuel mixture in order for an engine to operate at different speeds. A carburetor has two primary valves that allow that to happen, one above the venturi and one below. The top valve is called the choke, which when closed, restricts air from entering. This allows for a cold or starting engine to receive more fuel and run rich. The valve on the bottom is called the throttle. The more the throttle opens, the more air and fuel enter the combustion chamber, which produces acceleration.

Carburetor Functions

Carburetors are comprised of multiple different circuits that all serve their own purpose. There are seven primary circuits within a carburetor. These include float, choke, idle, main metering, power enrichment, and accelerator pump circuits. In the following sections, we’ll break down how all of a carburetor’s individual circuits function.

Carburetor Float Circuit

One of the most sophisticated, and arguably one of the most important circuits within a carburetor is the float circuit. In essence, the float circuit is the one that supplies fuel to the entire system. As such, it needs to be present and functioning correctly for all of the other carburetor circuits to function properly. To describe it simply, the float circuit is a miniature fuel tank. It is supplied by the vehicle’s main fuel tank, and is replenished continuously by a valve that opens when the fuel level gets low.

The amount of fuel in the small fuel tank, or “bowl,” is controlled by a “float.” The float is connected to a float needle which is then connected to a fuel inlet valve. The float is typically made of hollow plastic or metal and, unsurprisingly, floats on the fuel within the chamber. When the fuel level decreases, the float travels slowly toward the bottom of the chamber with it. As the float approaches the bottom, it actuates the lever to which it is attached. This allows the fuel inlet valve to open, replenishing the fuel in the tank.

As the fuel flows into the tank and raises the float once again, the valve is closed and fuel stops flowing into the bowl. In essence, that is how a carburetor float circuit works. It is also important to note that the level of fuel in the bowl matters a great deal. If there isn’t enough fuel in the float circuit, the engine will run lean. If there is too much fuel in the circuit, the engine will run rich.

Carburetor Choke Circuit

Once fueling has been dealt with, the next circuit of importance is the choke circuit. All carburetors have chokes, which are necessary to control the amount of air entering the engine. By controlling the amount of airflow, the choke also controls the air/fuel mixture. This is extremely important for cold starts and engine operation on extremely hot days. Both require a dramatically different ratio of air to fuel.

Since gasoline has an extremely difficult time vaporizing in negative-degree temperatures, a carburetor’s choke supplies the engine with a richer-than-normal air/fuel mixture by significantly limiting the amount of air coming into the system, creating a vacuum effect that sucks a massive amount of fuel from the main jet. Once the manifold reaches a high enough temperature to be able to vaporize the fuel effectively, the choke is no longer needed.

While cold weather/old start operation is the main reason for a carburetor choke, a choke is also needed for extremely hot temperatures as well. When temperatures in the engine bay reach an extremely high temperature, fuel can vaporize before reaching the venturi section of the carb. This can lead to vapor lock, preventing the engine from starting. Ultimately, the choke is an extremely important part of a carburetor’s functionality, especially in extreme temperatures.

Carburetor Idle Circuit

The idle circuit is one of the most nuanced and intricate circuits in a carburetor. It is typically the circuit that needs the most attention and adjustment. First, we need to understand what an engine at idle truly means. In essence, an idling engine is one where no external load is being placed on it. That means the throttle plate is nearly entirely closed. In that state, the engine isn’t able to produce enough pressure to draw fuel from the main metering circuit. To solve that issue, an idle circuit is required. This circuit typically consists of an idle jet, the idle bypass, an idle restrictor, an idle air bleed, and an idle mixture screw.

How the Carburetor Idle Circuit Works

That sounds like quite a bit to handle and the reality of it is that it is. Each component of the idle circuit is necessary and crucial for an engine to run properly. The idle circuit is generally activated by a vacuum under the throttle plate. That causes a low-pressure area in the idle passage, causing fuel to flow through the idle jet. Once fuel is introduced, it passes through the idle feed restrictor. The idle feed restrictor narrows in the center, beginning the air/fuel mixture process. The mixture then enters the idle bypass/idle feed well. The mixture relies on atmospheric pressure to push it up past the idle air bleed.

Once the air/fuel mixture passes the idle air bleed, more air is introduced to the system. The mixture is then forced to the idle port and idle mixture screw and then onto the throttle area of the carb. The mixture’s final location is the curb-idle discharge port located under the throttle plate.

It is important to remember that most of the components of the carburetor idle circuit are fixed in the amount of air/fuel that they supply. For example, the idle jet, idle bypass, and idle restrictor are all constants. For that reason, if the air/fuel mixture is off and the idle isn’t steady, the idle mixture screw can be used to adjust the air/fuel mixture. As the throttle plate opens, the idle circuit remains active and needs to be adjusted accordingly.

Carburetor Main Metering Circuit

While we have talked about carburetor functions that help an engine start and idle, the main metering circuit allows an engine to function at operating speeds. The central objective of the main metering circuit is to supply an adequate amount of fuel for an engine to operate at speed. As more fuel is introduced into the main fuel well, more air is needed as well. To accomplish that, air is bled into the well by a number of bleeder tubes. The increasingly aerated fuel is then atomized and emulsified more efficiently before entering the venturi.

Carburetor Power Enrichment Circuit

Technically speaking, a carburetor doesn’t need a power enrichment circuit. However, power enrichment circuits can play an important role in regulating air/fuel mixture when the throttle plate is partially open. Most carburetors, especially high-performance carbs do have one though. Since the main metering circuit is responsible for air/fuel mixture under both wide open throttle and partial throttle conditions, it always supplies enough fuel for maximum attack. This means that the main jet is supplying more fuel than necessary at most times during operation.

A power enrichment circuit lets the main metering circuit take a back seat during wide-open throttle operation. A power enrichment circuit utilizes manifold vacuum to operate a valve that supplies the main metering circuit with a significant amount more fuel at wide open throttle.

Carburetor Accelerator Pump Circuit

For a carburetor to work effectively, it needs to overcome a number of issues caused by the design itself. Due to the fact that a carburetor relies entirely on pressure differentials and fluid dynamics, the changing state of multiple parts on a carb have an impact on internal pressures. When the throttle plate opens, a drop in vacuum occurs before more air and fuel are introduced to the combustion chamber. While there is only a slight lapse in power when this happens, there would be a noticeable hesitation when hitting the gas if left unaddressed. That is where the accelerator pump circuit comes into play.

The main purpose of an accelerator pump circuit is to shoot fuel directly into the venturi. This covers for the lapse in internal pressure when the throttle plate is opened. The accelerator pump is essentially a diaphragm that is connected to the primary throttle shaft. When the throttle is mashed, the accelerator pump is activated. That forces fuel through a tube which then hits the top of the booster, atomizing it for better combustion.

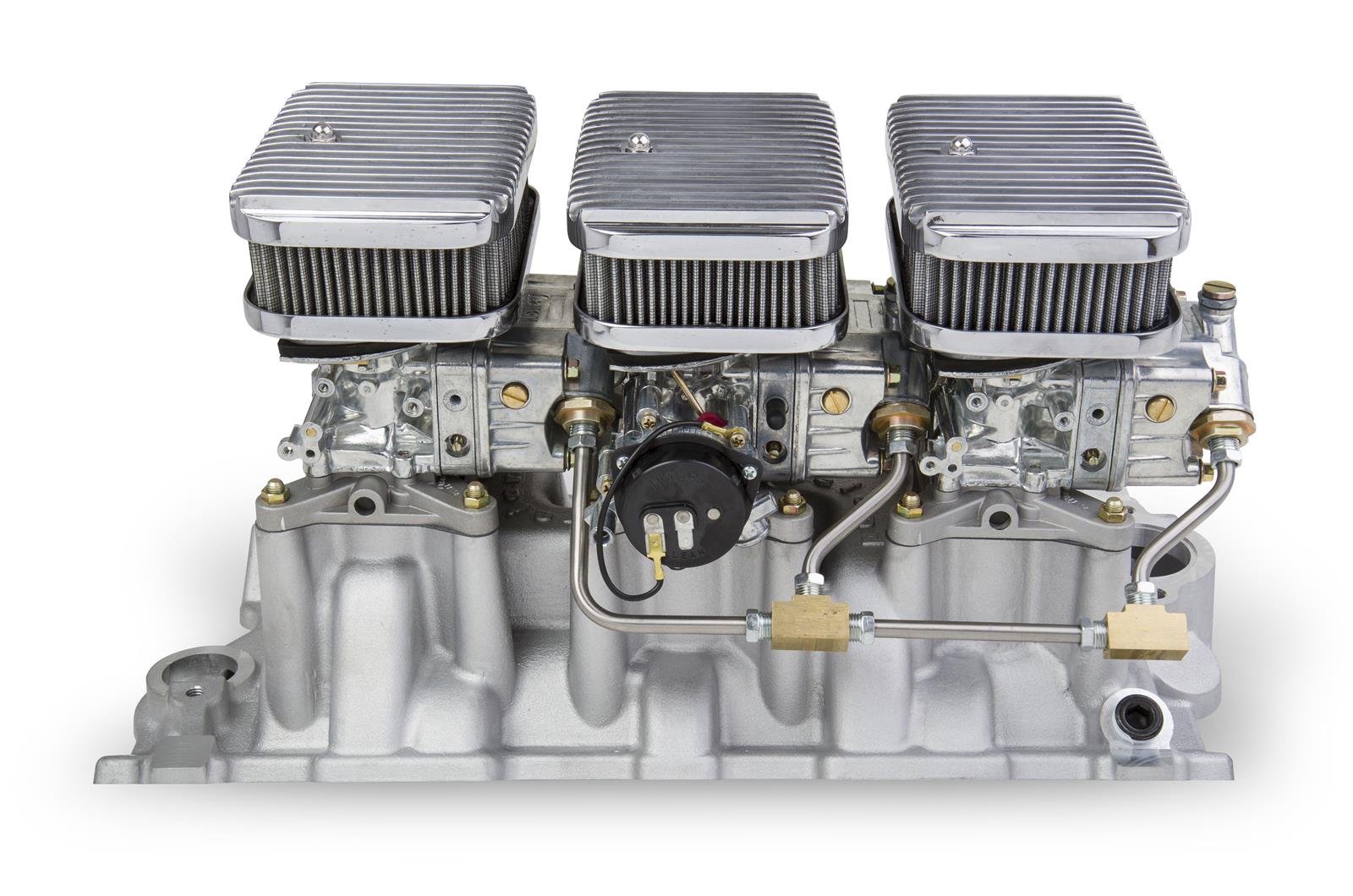

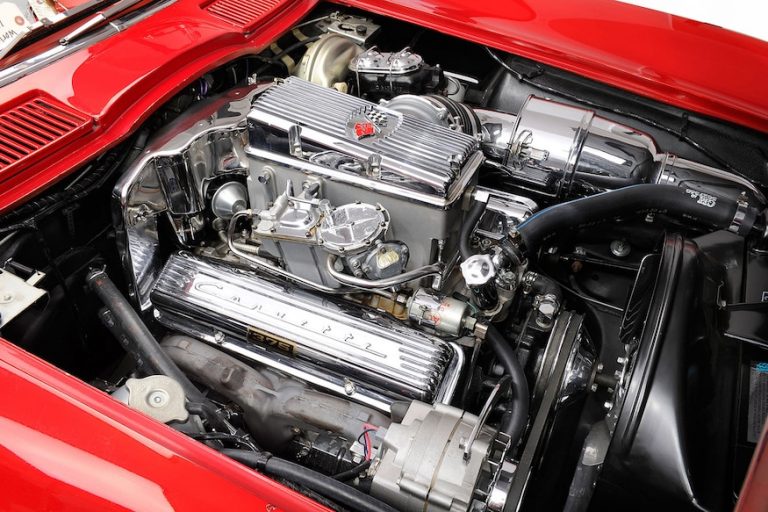

Multiple Carb Setups

Some engines, like those found on a lawnmower or chainsaw typically only need a single-barrel carburetor to operate efficiently. Some high-performance engines utilize a multiple-carburetor setup. There are significant benefits to having additional carburetor barrels. The primary reason for multi-barrel carb setups is increased airflow.

Before performance carburetors were as commonplace as they are today, many carbureted engines were limited by the amount of air a single-barrel carburetor could intake. This limited flow capacity led to the addition of multiple barrels to supply high-performance engines with additional airflow. Obviously, new manifolds were needed to accommodate the additional carburetor barrels, which would dramatically boost performance for some manufacturers. Pontiac Tri-Power manifolds are perhaps the most famous example of this. That was the setup that everyone wanted in the 1960s.

Multi-barrel carb arrangements have worked in different ways over the years. Initially, high-performance V8s used a single carb up until a certain point, around 70 percent throttle, before another carb was introduced. Another benefit of a multi-carb arrangement is better fuel flow characteristics for all of the cylinders. With a single carb central between the banks of the engine, only the central cylinders would get optimal fuel flow. With a multiple carb arrangement, all of, if most of, the cylinders would receive better fuel flow.

What Is A Carburetor? Summary

Before the days of electronic fuel injection, car manufacturers had to rely on a more analog way of providing an engine with a proper air/fuel mixture. The carburetor was the all-inclusive solution to that issue. While you would expect a carburetor to be a simpler device than what we are used to nowadays, carburetors are actually very intricate and precise devices that require a decent amount of knowledge to understand, tune, and operate.

Due to the fact that carburetors rely almost entirely on the Bernoulli principle, there are quite a few fluid dynamics issues to be overcome for a carburetor to function properly. For example, the changing pressure differentials within a carburetor necessitate the need for multiple different circuits to serve their own purposes. These circuits include the float circuit, the choke circuit, the idle circuit, the main metering circuit, the power enrichment circuit, and the accelerator pump circuit. Each of these circuits plays a crucial role in allowing an engine to receive the right amount of air and fuel at a particular engine speed.

While carburetors are antiquated technology at this point due to the advent of fuel injection, carburetors were a crucial stepping stone in automotive history. Most cars before 1975 use a carburetor, or multiple carburetors, to function. Chances are, if you are into muscle cars, you’ve had to deal with them once or twice.

If you enjoyed this article and are looking for more muscle car engine content, we have more! Check out our Best Mustang Engine in History article. If you have carburetor questions or stories, leave a comment below!