Ultimate Ford 429 Engine Guide

Meet Austin

Austin has been a muscle car enthusiast since an early age with his Dad having a collection including a 1965 Mustang, 1968 Mercury Cougar, and a 1969 Mustang Mach 1 among many others. Austin received a technical writing degree from University of Colorado Denver with the intentions of becoming an automotive journalist. His automotive knowledge, enthusiasm, and hands on experience allow him to craft detailed, accurate, and high-quality articles for the passionate Muscle Car Club audience.

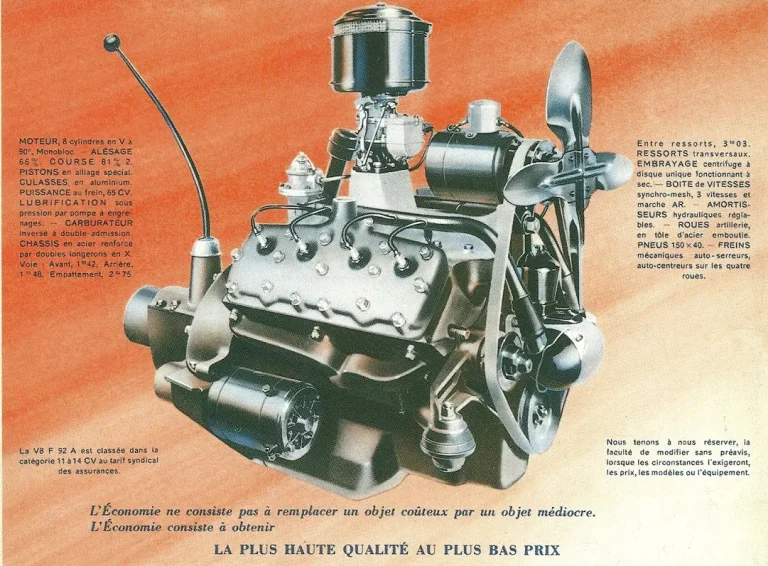

The Ford 429 is one of the most iconic big-block V8s that Ford has ever produced. Between its introduction in 1968 and its discontinuation in 1998, the 429 powered everything from the Mustang to the Ford F-Series. In addition to the base passenger model, Ford eventually realized the massive potential of the 429 and created some iconic variants of the 7.0L V8 including the 429 Cobra Jet, Super Cobra Jet, and Boss.

In this guide, we’ll take a look at the Ford 429 in detail, covering the engine’s history, specs, applications, common problems, and most popular modifications.

Ford 429 Engine History

In the late 60s, the Ford FE and MEL engine series were approaching their tenth birthday and were in need of a refresh. Obviously, both the FE and MEL engines served the Blue Oval well, as they are still celebrated big blocks to this day. In 1968, the Ford Lima plant was fitted with new tooling and began producing the Ford 385 engine series, starting with 429 cubic-inch and 460 cubic-inch V8 big blocks.

The Ford 385 engine series gets its name from the 3.85” stroke length of most of the engines in the series, excluding the 429, which had a 3.59” stroke. However, they are often also called “Lima” engines after the manufacturing plant in which they were produced. Looking at the 385 engine catalog, it is no secret that the 429 is the most celebrated of the bunch. Its performance pedigree and famous variants (including the 429 Cobra Jet, 429SCJ, and 429 Boss) cemented the 429’s legacy firmly in the history books as the Ford engine to have between 1968 and 1973. It firmly overshadowed the other 385 big blocks of the time, including the Ford 370 and Ford 460.

Despite being known for its performance applications underneath the hoods of a number of famous pony cars, the 429 was as versatile as it was feared on the drag strip. In addition to being used in cars like the Thunderbird, Mustang, and Mercury Cougar, the 429 was also used in light and heavy truck applications. From 1977-1998, its impressive torque figures made it a fantastic powerhouse for the Ford medium-duty F-Series, along with commercial truck applications like the Ford B-Series and C-Series.

Ford 429 Engine Specs

| Engine | Ford 429 V8 |

| Engine Family | Ford 385 Engine Series |

| Model Years | 1968-1998 |

| Displacement | 429 cid (7.03 liters) |

| Aspiration | Naturally Aspirated |

| Configuration | 90° V8 |

| Compression Ratio | 10.5:1 – 11.3:1 |

| Bore and Stroke | 4.36” x 3.59” |

| Valve Train | Overhead Valve, 16-valve (2 val/cyl) |

| Fuel System | Carburetor |

| Head Material | Cast Iron / Aluminum |

| Block Material | Cast Iron |

| Horsepower Output | 320-375 (rated) horsepower |

| Torque Output | 450 lb-ft |

Ford 429 Vehicle Applications and Production Years

The Ford 429 is one of the most versatile big blocks in the Blue Oval’s catalog. Throughout its three-decade-long build cycle, it was not only used in pony cars and intermediate-size chassis, but also a number of medium and heavy-duty trucks. These are the cars that used the 429:

- Ford Thunderbird (1968–1973)

- Ford Mustang (1969–1971)

- Ford Mustang Boss 429 (1969–1970)

- Ford/Mercury full-size (1969–1973)

- Ford/Mercury intermediate (1969–1973)

- Mercury Cougar (1971)

- Ford medium-duty F-Series (1977–1998)

- Ford F-600/F-700/F-800

- Ford B-Series (1977–1989)

- Ford C-Series (1979–1987)

- Ford C600/C700/C800

- Ford L-Series “Louisville Line” (1977–1991)

- Ford L900

Ford 429 Engine Design

All of the engines in the Ford 385 engine series shared very similar overall construction, with the 429 and 460 being especially similar. In fact, the two engines even shared the same connecting rods (in standard 429 form) and overall block design.

In line with the 385 namesake, the 429 has a 4.36” bore (the same as the Ford 460) and a 3.59” stroke for a total displacement of 429 cubic inches. That makes the 429 the second largest displacement production engine in the 385 engine series, outside of the 514 and 572 crate engines. The 429 has a more modern design than previous big block Fords, utilizing thin wall block casting. There is nothing particularly special about the standard 429’s overall construction. It featured two-bolt mains, a cast iron crankshaft, forged “C8VE-A” connecting rods, a relatively tame hydraulic camshaft, and unimpressive yet reliable 2-barrel and 4-barrel carburetor options.

In addition to the standard 429 passenger engine, Ford eventually came around and created performance variants of the 7.0L V8. Those are truly the engines worth talking about. In total, there were three different performance variants of the 429 including the 429 Cobra Jet, 429 Super Cobra Jet, and the 429 Boss. Those engines deserve sections of their own, so let’s talk about the design of those engines.

429 Cobra Jet/429 Super Cobra Jet

It wasn’t long at all before Ford realized that the big-displacement 429 had more potential than was being taken advantage of in the Mustang and Thunderbird. While the 429 in its barebone state was nothing to scoff at, the high-flowing nature of the 429’s poly-angle heads and massive port sizing made the 429 a more-than-formidable starting point for an engine even more potent. In 1970, Ford introduced the 429 Cobra Jet.

The 429 Ford Cobra Jet pumped out 370 horsepower, while the Super Cobra Jets pushed out 375 horsepower. They also made a healthy 450 lb-ft of torque, which made for total increases of 35-40 horsepower and 10 lb-ft over the 428s. To get to those figures, the Cobra Jet featured a 700 CFM Rochester 4-barrel carb, larger intake and exhaust valves (2.24” and 1.72” respectively), smaller combustion chambers leading to an increase in compression up to 11.3:1, and stronger main-bearing webbing.

The 429 Super Cobra Jet took things even further, with some serious changes that took a committed enthusiast to be able to appreciate. The 429SCJ was fortified even further against abuse with four-bolt main bearings, forged aluminum pistons in lieu of cast, and the introduction of an oil cooler to the front radiator support. In terms of performance, the 429SCJ received a bespoke intake manifold, complete with a massive 780 CFM Holley 4-barrel, and the switch to a solid-lifter camshaft that required regular manual adjustments.

The 429 Cobra Jet and Super Cobra Jet were toys meant for the big boys with fat wallets, as the upgrade from the standard 429 to the CJ cost around $500 in 1970 and an extra $700 for the SCJ.

Ford 429 Boss

Outside of the 429 Cobra Jet variants, there is one more 429 variant that deserves some screen real estate here. In fact, it is the hardest-core 429 option that Ford offered, and for good reason. Ford released the 429 Boss as a homologated engine for NASCAR in 1969. At the time, the 426 HEMI owned the oval, and Ford intended on taking the crown with the 429 Boss. As a result, Ford created 1,358 429 Boss engines that were all placed in the Mustang instead of the Torino, which was Ford’s entrant for the 1970 NASCAR season.

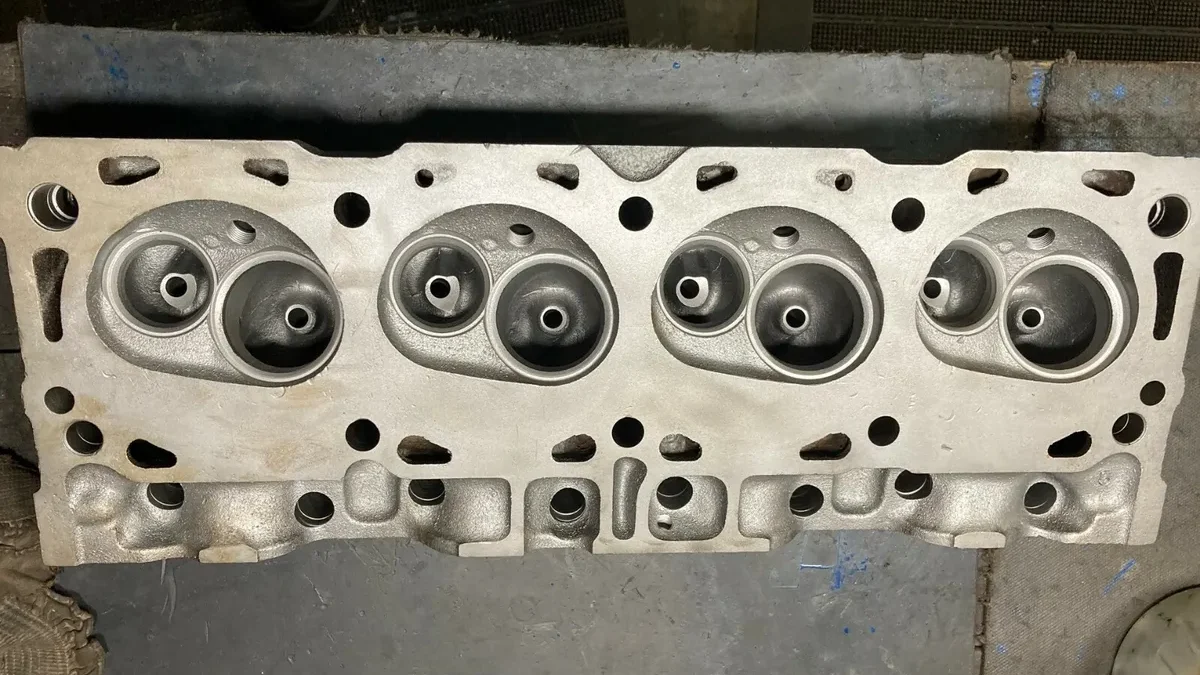

Compared to the standard 429 and 429CJ, the 429 Boss received an entirely new and innovative cylinder head design. Often called the 429 “Semi-HEMI,” the 429 Boss featured modified aluminum heads that used a semi-hemispherical combustion chamber design and featured large canted valves similar to the Chevy big block. The racing engines differed from the street engines in a number of ways, but the main difference is the port size, as the race version’s valves were too big for street use.

Unlike the 429 Super Cobra Jet, the 429 Boss returned to a hydraulic camshaft in 1969. The 1970 version of the engine used a solid cam. It also used four-bolt mains, stronger main bearing webbing, and a different oiling system from the rest of the 429 range. While Ford advertised that the 429 Boss was capable of 375 horsepower, most enthusiasts agree that the number was closer to 475. The Mustang 429 Boss was only available from 1969 to 1970, making it an exceptionally rare and sought-after model in the collector world.

Ford 429 Common Problems & Reliability

In all honesty, Ford 385 big blocks, including the 429, have a reputation for reliability. Most owners easily achieve 200,000 miles or more with virtually no serious issues, thanks to the lasting build of the 385. The 429’s use in civilian and work trucks goes to show that Ford felt that it was reliable enough for more rugged applications. Most of the 429’s common problems nowadays are due to the age of the engine at this point. The most common Ford 7.0L V8 engine problems include:

- Broken Exhaust Manifold Bolts

- Timing Chain Issues

- Oil/Coolant Leaks

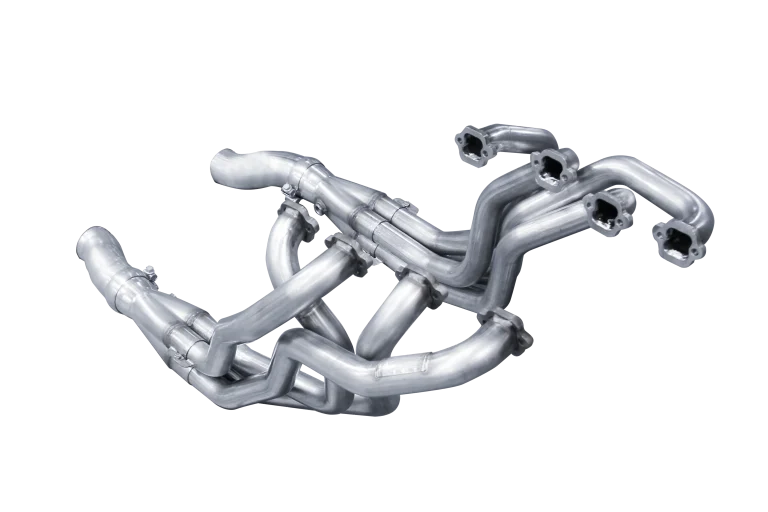

Broken Exhaust Manifold Bolts

Broken exhaust manifold bolts are a common issue on all Ford 385 big blocks, especially at this point in their life cycle. The problem happens over time as the exhaust manifold continues to expand and contract as it repeatedly heats up and cools. Through that continued heat cycling, the bolts fastening the exhaust manifold to the exhaust ports wear out, eventually leading to the bolt heads snapping off. That’s seriously annoying, as it is a difficult thing to fix.

Weather is another factor that exacerbates the issue, especially if you live in an area with extreme climate changes. If you live in a snowy area, the heat cycling is more extreme, in addition to the added corrosion due to road salt.

Timing Chain Issues

Timing chain issues on old engines are relatively common, especially on high-mileage ones. That is also the case for the Ford 429. Over time, the timing chain develops slack from internal component wear. That isn’t due to anything going wrong, but the continual tension from the timing chain tensioners causes play to develop in the chain.

If the timing chain develops too much slack, it can cause the engine to jump timing, with the chain skipping over the teeth of the timing gears. Since the Ford big block is an interference engine, a jumped timing event can do serious damage to the engine’s cylinder head. In some cases, the incorrect timing can cause the pistons to smash into the valves in the cylinder head, necessitating a rebuilt head. Since timing chain wear can cause such catastrophic damage to the engine, it is important to replace the timing chain every 70,000-80,000 miles.

Oil/Coolant Leaks

Given that most Ford 429 engines are over 50 years old at this point, it is no surprise that oil leaks are common. The most common oil leaks include the rear main seal, the valve cover gasket, the oil pan gasket, and the oil cooler. Outside of the common oil leak locations, there are also some common coolant leak locations. The timing cover and oil cooler are the most serious problem areas for coolant leaks. Failure to address the issue promptly will result in the coolant/oil mixture ruining the engine.

Ford 429 Performance Upgrades

The Ford 429 big block is one of the most celebrated Ford engines ever made, and the majority of that praise comes from its performance capabilities. As the 429 has gained even more of a cult following, there are endless modifications available for the 7.0L at this point. The recipe for a big-power 429 is pretty straightforward:

- Cylinder Head Upgrade

- Intake Manifold Upgrade

- Carburetor Upgrade

- Camshaft Upgrade

Cylinder Head/Intake Manifold Upgrade

The easiest and most cost-effective way to add heaps of power to a 429 build is by upgrading the factory cylinder heads and intake manifold. If you are trying to keep costs low, a quality port and polish job can make a world of difference when it comes to the breathability of the factory heads. 429 heads are known to have serious casting imperfections, especially in the exhaust ports, so a good port job can truly wake up the engine.

If you are looking to change up the factory heads with ones that have larger valves and ports, 429 Police Interceptor cylinder heads are the freest-flowing options that can be picked up for relatively cheap, despite getting harder and harder to find these days. Even harder to find are D0VE Cobra Jet and Super Cobra Jet heads, but they are worth the additional coin if you can get your hands on some. The CJ/SCJ cylinder heads feature massive 2.25 intake, and 1.75 exhaust valves which truly turn the 429 into a more potent animal. There are a number of quality aftermarket head options available as well, including Ford Racing Technology’s own “CJ” aluminum heads, which not only reduce heat but also feature even larger intake and exhaust valves than the original CJ heads.

There are also a number of worthwhile intake manifold upgrades available for the 429 as well. Dual-plane manifolds, like the Weiand Stealth 8012, are a good option for a slightly juiced street car, as the longer runners bump up low and mid-range torque significantly.

Carburetor Upgrade

Choosing the right carburetor is one of the most crucial elements of a 429 power build. It is important to remember that each 429 variant uses a different factory carburetor. The 700 CFM Rochester 4-barrel carb found on the Cobra Jet and the 780 CFM Holley 4-barrel found on the Super Cobra Jet are excellent options for an upgrade on a standard 429, but they are hard to find. However, there are comparable new carbs available that will work just as well.

A 750 CFM Holley with vacuum secondaries is a great option for a moderate street build with ported heads and a cam. You might not need that much flow if you aren’t planning on going all out with the top end. In that case, a 650 or 700 CFM Holley is the best bet.

Ford 429 Legacy

As a replacement for the Ford FE and MEL engine series, the 385 Lima series introduced new heights in performance, reliability, and versatility. The 429 is unquestionably the crown jewel in the 385 lineup, as its use in the Mustang CJ, SCJ and Boss cemented its legacy. Even outside of sportier applications, the 429’s versatility is unparalleled, proven by its use in everything from the Mercury Cougar to the Ford F-Series. Its design causes very few common problems, making it an extremely reliable option. In fact, most of its issues, including broken exhaust manifold bolts, timing chain issues, and coolant leaks are the result of age more than anything else.

As a factory engine, the 429 has one of the highest power potentials of any big block that Ford ever made. The 429’s bore spacing and tall deck height allow for a ton of stroker kit options to increase displacement significantly. Cylinder head and intake manifold upgrades can dramatically improve how the engine breathes, culminating in a ton of additional power. Not to mention, aluminum heads and manifolds can decrease the engine’s weight by a couple of hundred pounds.

From the standard 429 to the 429 Cobra Jet to the 429 Boss, the Ford 429 will go down in history as one of the best American big blocks ever created.

You left out the Falcon

The 429 was produced from 1068 to 1973 not to 1998

1968 Hell i cant even get it right.