Chevy 427 Big Block Guide

Meet Austin

Austin has been a muscle car enthusiast since an early age with his Dad having a collection including a 1965 Mustang, 1968 Mercury Cougar, and a 1969 Mustang Mach 1 among many others. Austin received a technical writing degree from University of Colorado Denver with the intentions of becoming an automotive journalist. His automotive knowledge, enthusiasm, and hands on experience allow him to craft detailed, accurate, and high-quality articles for the passionate Muscle Car Club audience.

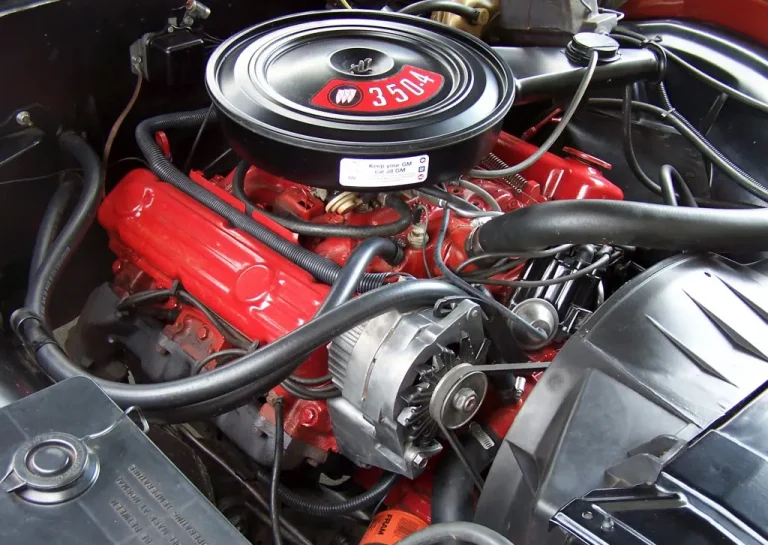

The second generation of Chevy Big Blocks won’t ever be forgotten. In just 3 short years, the Mark IV Chevy 427 big block cemented its status as the bad boy on the block in the muscle car world. Ranging from the 390 horsepower, low-compression L36 to the 560 horsepower, race-derived L88, the Chevy 427 proved to be a relentless powerhouse for a number of production Chevy vehicles between 1966 and 1969.

The Mark IV 427 Big Block represented a big step for Chevrolet, as the 427, and Mark IV V8 platform as a whole, differed significantly from the previous W-series design. The Mark IV ditched the previous chamber-in-block design in favor of a more traditional wedge chamber attached to a 90-degree deck. Valve placement was also altered, giving them an inclined position in which they opened away from the cylinder walls. These changes produced significant improvements to volumetric efficiency and better performance higher in the rev range.

What Cars Use the 7.0L Chevy 427 Big Block

Chevrolet Biscayne 1966–1969 (L72)

Chevy Caprice 1966–1969 (L72)

Chevrolet Impala 1966–1969 (L72)

Chevy Corvette 1966–1969 (L36, L68, L72, L88, L89)

Chevrolet Camaro 1968–1969 (L72, ZL-1)

427 Big Block Chevy Specs

On paper, all of the Chevy 427 engines from 1966-1969 share a similar construction. The most important similarity is displacement. All seven 7.0L Big-Block variants have the same 4.251 x 3.760 stroke and bore. While displacement is the same on all 427 engines, compression ratio varies a fair amount between them. L36 and L68 engines have a 10.25:1 compression ratio, L71, L72, and L98 engines have an 11.0:1 ratio, and L88 and ZL-1 engines have a 12.5:1 ratio. In a time when forced induction wasn’t as popular, aggressive cams and higher compression made a big difference to horsepower.

Other than differences in compression ratio, engine construction materials also vary between them. For instance, L36, L68, L71, and L72 all have cast iron heads. In comparison, the L88 and L89 feature rectangular port aluminum heads. The ZL-1 is constructed entirely from aluminum. Additionally, the L72 uses a high-rise aluminum intake manifold. Top 427 engines, including the L71, L72, L88, L89, and ZL-1 engines, all use forged steel crankshafts for added strength.

Induction method is another key differentiator between the 427 models. Chevy tended to provide a four-barrel carbureted and optional three-two barrel Tri-power option for each main spec engine. For instance, the L36 and L68 are nearly identical engines other than the carburetor type. The less powerful engine option would receive the four-barrel carb, while the higher-tier model would receive the Holley three-two barrel arrangement. The same can be said for the L71 and L72 427s.

Chevy 427 Big Block Variants

Over the course of the 427 Big-Block run between 1966 and 1969, Chevy developed seven different variants. Some 427 variants are similar in construction and power production, while others feature different build materials, a different combination of performance parts, and different compression ratios. While they are all unique in their own way, they share the common thread of being big-block 427-cu.in. engines.

Chevy L36 Big Block 427

Available from 1966-1969 for Corvette applications only

The Chevy L36 427 is the little brother of the 1966-1969 big-block lineup. Compared to the other 7.0L V8s to follow, the L36 is the least powerful. The L36 was the first of the Mark IV 427s to hit the streets in 1966. The L36 has the lowest compression ratio of the 427 engines (tied with the L68), resulting in a comparably low 390 horsepower rating. While the L36 is down on horsepower compared to the rest of the 427 lineup, it still produces 460 lb-ft of torque. That is the same figure across the board, regardless of the 427 configuration.

The L36 is also limited by its use of oval-port cast iron heads, which don’t flow nearly as well as the rectangular-port heads found on the higher-horsepower 427 engines. The L36 427 made use of a Quadrajet 4-barrel carburetor and a mild hydraulic lifter cam. Nearly all L36 427s are two-bolt main engines, with the exception of a couple of rarities that feature four-bolt main construction.

Chevy L68

Available from 1967 – 1969 for Corvette applications only

Following the release of the L36 and L71 427 engines in 1966, Chevy released an updated version of the L36 low-compression design for 1967. The L68 is nearly identical to the L36 design, even sharing the same 10.25:1 compression ratio. In fact, the L68 was less of a unique engine, and rather an engine option or upgrade package for the L36. However, the L68 has some notable improvements over the L36.

The induction system is the most obvious difference between the L36 and L68 427 configurations. While the L36 utilizes a Quadrajet 4-barrel carburetor, the L68 features a Tri-power carb arrangement. The three-two barrel arrangement for the L68 also features a distinct triangular air cleaner. Like the L36, the L68 is a two-bolt main engine. The four-bolt main construction was saved for the more powerful 427 7.0L Chevy engines.

Chevy L71

Available in 1967-1969 Corvettes

As we have already established with the L36 and L68, some of the 427 configurations differed only marginally. In much the same way that the L68 is really just a slightly modified engine option for the L36, the L71 is really just an L72 with a modified intake system. In fact, the L71 features the same modification done to the L68 which differentiated it from the L36.

Instead of equipping the L71 with the standard four-barrel Holley carburetor, the L71 is equipped with a three-two-barrel carb Tri-power setup. The result is an increase in fuel flow by around 220 cfm compared to the L72. The notable increase in fuel flow garners around 10 horsepower over the L72, bringing the number to 435 horsepower. Other than the intake system, the L71 and L72 are identical in every way.

Chevy L72

Available in 1966 Corvettes and 1966-1969 Caprice, Bel Air, Impala, and Biscayne models. The L72 was also available in 1969 COPO Camaros and Chevelles

The Chevy L72 427 was released the first year that the Mark IV 427 was available, alongside the L36. Compared to the L36, the L72 is the significantly higher-performing option. In 1966, the Chevy L72 427 was the most powerful engine option available in the Corvette. The initial 450 horsepower rating made the L72 the engine to have throughout its production run between 1966 and 1969.

Unlike the L36 and L68, the L72 Big-Block was available in other full-size Chevy models outside of the Corvette. In 1966, 1,856 L72 427s made it into full-size Caprice, Bel Air, and Biscayne models. Only a dozen L72 engines were designated for passenger cars in 1967, with the L72 being a more popular engine for big Chevys in 1968. In 1969, the Chevy L72 was available to order through a Chevy Central Office Production Order for placement in a Chevelle or Camaro.

The L72 is the 427 to have, outside of the highly rare L88, producing between a factory-rated 425-435 horsepower. In reality, they likely make a significant amount more. Compared to the L36 and L68 427s, the L72 has a notably higher compression ratio of 11.0:1. The L72 features additional strength and performance-increasing parts like a four-bolt main construction, high-flow rectangular port heads, forged crankshaft, and a solid lifter cam.

An important attribute of the L72 is Chevy’s use of a Holley four-barrel carburetor. This is important to note, as the carburetor choice is a distinct difference between the L72 and L71.

Chevy L88

Available in the L88 Chevy Corvette only between 1966-1969

The Chevy L88 is the top dog of production Chevy 427s. Used in only 216 specially made L88 Corvettes from 1966 to 1969, it is also one of the rarest Chevy Big Block 427 out there. The L88 was listed by Chevy as being less powerful than the L72 to throw buyers off of the L88’s scent. In actuality, the L88 is one of the most powerful engines ever put under the hood of a Corvette. The 430 horsepower rating is laughably low, as most L88s put out more than 550 horsepower.

The L88 Big-Block was designed to be a race engine right from the factory. It features lightweight aluminum heads, a barely street-able performance solid lifter cam, a forged crankshaft, a massive Holley 830-cfm carburetor, 7/16” pushrods, forged aluminum pistons, and a 12.5:1 compression ratio. There are other performance distinctions too, but those are the main ones.

The ultimate goal of the L88 Corvette was to be a performance-only model, with as few of them going to the civilian population as possible. The chief Corvette engineer, Zora Arkus-Duntov, was an avid racing fan and wanted to release a Vette specially designed for the track. The L88 427 Big-Block was a key component of making that goal a reality.

Chevy L89

Okay, if you aren’t familiar with the L89 and its construction, get ready. It can get somewhat confusing. So, we’ve already established that the L71 is essentially just an L72 427 with a Holley two three-barrel Tri-power carb setup in place of the L72’s four-barrel carb. However, in essence, the L72 and L71 are identical in every other way except for that. The situation is very similar between the L71 and L89.

Like the L68 engine upgrade, the L89 engine didn’t exist as a standalone engine from 1967-1969. Instead, the L89 was an additional option to the L71 engine option. So, for instance, if you wanted an L89, you’d have to select the L71 engine option for the L72, then the L89 option within that L71 pick. Needless to say, not many people went that deep.

When the L89 addition was selected from the factory, the cast-iron heads on the L71 were switched with closed chamber aluminum heads. The swap to aluminum heads doesn’t produce any additional horsepower over the L71. However, they did remove around 70lbs from the 7.0L V8’s overall weight. That makes a big difference in terms of handling characteristics and performance. Additionally, the L89 option increases the L71’s exhaust valve face diameter. For the L89, the exhaust valve size was increased to 1.88.” That does increase horsepower over the L71 by around 10 hp.

Chevy ZL-1

Available in limited Camaros and Corvettes in 1969, other racing applications

Just like the L88, the ZL-1 is a very rare beast and perhaps even more sought after than the L88. Like the L88, the creation of the ZL-1 was very much focused on performance and racing applications. In terms of construction, the ZL-1 and L88 are extremely similar engines. The primary difference between the two is the ZL-1’s all-aluminum construction. With an aluminum block and heads, the ZL-1 weighs in at only 575lbs.

The ZL-1’s aluminum cylinder heads evolved over the years, the same as the L88. In its initial form, the ZL-1 427 features a closed design. By the the1969 model year, the closed aluminum heads were replaced with open chamber aluminum heads. In addition to the all-aluminum construction, the ZL-1 also received an even more aggressive performance cam than the L88. The new cam made it nearly undrivable under normal street conditions.

The ZL-1 was used in numerous race cars over the years, including the McLaren M8B. Many of the 69 manufactured ZL-1 Camaros were used in the NHRA’s Super Stock Class. Only two production Corvettes received the ZL-1 performance engine, as it doubled the price of the base car.

Chevy 427 Engine Upgrades

In the Chevy Big Block 427 and 427 Corvette communities, engine modifications are getting rarer and rarer. It makes sense, as the values of classic 427 Big Blocks and the cars that they came in skyrocket. With that being said, there is nothing wrong with wanting a bit more power from a high-performance Chevy V8 that was built to be abused. Of course, as there are so many variants of the Chevy Big Block 427, engine modifications can vary significantly.

With that being said, there are a few blanket modifications that most 427 Chevy owners tend to universally agree on. Building a Chevy 427 Big Block is a massive topic that deserves its own screen real estate. For that reason, we’ll only brush the surface in this article. In this guide, we’ll mainly be focused on reversible 427 modifications. That is in the interest of preserving rare factory parts. If you are interested in learning more, leave a comment below and we’ll revisit the topic.

Upgraded Chevy 7.0L Big Block 427 Cam

When considering upgrades for a 427 Chevy Big Block, one of the natural considerations is the cam. That mainly boils down to the fact that hydraulic roller cams can be a significant upgrade to the factory flat-tappet cam found in 427 Big Blocks. In comparison to flat-tappet cams, hydraulic roller cams provide better performance and enhance reliability as well. In the past, it was believed that flat-tappet cams were the only form equipped for high-rpm applications, but that has certainly changed with modern advances.

Hydraulic roller cams allow for faster ramp rates because of their rounded design. Compared to flat-tappet cams that are more pointed, hydraulic roller cams create higher lifts for a longer segment of their overall duration. For that reason, a more aggressive cam can be used without damage. While a hydraulic roller cam might provide better performance and reliability, upgrading to one in your 427 Big Block will require new lifters, pushrods, springs, valve seals, and rockers.

Alternatively, some Big Block Chevy 427 owners choose to stick with a flat-tapper cam with a more aggressive grind. Even without a hydraulic roller cam, you can see a significant increase in horsepower from installing a more aggressive flat-tappet cam.

Lowering Compression of 427 Big Block Chevy

The 427 Big Block came from a very different time. Back then, high-octane (Ethyl) fuel was readily available and offered practically everywhere. Now, in today’s market, you’ll be lucky to find octane levels higher than 93. Even that is only available in specific parts of the US. Even in the low-compression L36 Big Block 427, the compression ratio was still 10.25:1. For the higher performance L71 and L72 Big Blocks, the compression was even higher at 11:0. Since compression is so high, 427 Big Blocks require high-octane fuel to prevent detonation in the cylinders. That often requires 427 Big Block owners to mix their own high-octane fuel. That’s a serious pain in the neck.

However, many Big Block 427 Chevy owners have worked around this issue by reducing the engine’s compression. Generally, this is done through a combination of piston selection, gasket choice, and head shaving. Domed pistons are perhaps the best option and dome volume is dependent on your application. L71 heads are 100cc, so using a smaller 16.8cc dome piston can significantly reduce compression. However, that will have an effect on valve-to-piston clearance, and might require valve reliefs on the pistons. You’ll also want a thicker head gasket in combination with the new pistons. You’ll want a ratio under 10.1:0 to run with modern pump gas.

While this Chevy 427 Big Block modification will ultimately sacrifice a bit of power, the added convenience of not needing to mix your own gas every time you need to fill up is well worth a few ponies.

Chevy 7.0L Big Block Headers

This one is a no-brainer. Headers are one of the go-to modifications for pretty much every performance V8 engine in history, and the same goes for the 427 Big Block. It is no secret that the factory 427 iron exhaust manifold is very restrictive. Unlike the factory Big Block 427 exhaust manifold, which collectivizes the exhaust gasses from all of the cylinders near the head and dumps it into a collector, Big Block headers allow each cylinder its own primary tube that carries exhaust gasses to the collector.

The result of the increased length and independent runners is an increase in high-RPM performance compared to the factory exhaust manifold. The most common header upgrade for 427 Big Blocks, almost universally, is a set of Hooker 2” long-tube headers. Long-tube headers move the torque and power band up the rev range, which is ideal for racing applications. Ultimately, a good set of 2” headers will allow your Chevy Big Block 427 to breathe much more effectively. Some tests, like this one performed by MotorTrend, showed that a simple 2” header upgrade can yield up to 80 horsepower and 80 lb-ft of torque.

Most people with 1966-1969 Big Block 427 Chevelles, and other full-size Chevy models with the L72, complain that 2” headers barely fit in the chassis, especially with power steering. Quite a few 427 owners say that they have to dent 2” headers to make them fit around the power steering pump and lower control arm.

Big Block 427 Chevy 7.0L V8 Summary

As we have already established, the 427 Big Block is one of Chevy’s most beloved engine series. The 427 powered some of Chevy’s most iconic cars from the muscle car era and established itself as an undisputed behemoth under any hood. Throughout the 427 Big Block’s three-year production cycle, 7 distinct variants were placed in a number of Chevy cars, ranging from full-size, family-oriented cars like the Biscayne, to famous C2 and C3 Corvettes.

Generally speaking, the 427 line could be split into three unique camps. The first is the low-compression segment, which is comprised of the L36 and L68 engines. The 10.25:1 compression of those models, in addition to a few other key differences, were the lower tier 427 options as they didn’t produce quite as much power as the 11:0 compression 427s. In contrast, the 11:0 compression L72, L71, L89 427 variants were the high-performance 427 options at the time. In addition to other significant construction-related upgrades, the high-compression models significantly outperformed the low-compression models in terms of sheer horsepower. Finally, the race-trim 427s include the L88 and ZL-1 variants that were essentially purebred for the track. With 12.5:1 compression, forged internals, and massive carburetors, the highest 427 trim level engines still remain some of the most powerful that Chevy has ever produced.

Was the L88 built at the Tonawanda NY Engine plant?

Hey Brian,

Yes, all of the L88 castings were built at the Tonawanda engine plant in 1967. If you are interested in learning more about the L88, check out our L88 Engine Guide.