6.4L HEMI Engine Guide

Meet Austin

Austin has been a muscle car enthusiast since an early age with his Dad having a collection including a 1965 Mustang, 1968 Mercury Cougar, and a 1969 Mustang Mach 1 among many others. Austin received a technical writing degree from University of Colorado Denver with the intentions of becoming an automotive journalist. His automotive knowledge, enthusiasm, and hands on experience allow him to craft detailed, accurate, and high-quality articles for the passionate Muscle Car Club audience.

The 6.4L HEMI represented a new leap forward in the GEN III HEMI lineup, following the 6.1L which had quite the reputation of its own. From 2011 to 2021, the 392 HEMI, as it was called alternately, powered the bulk of Chrysler’s performance lineup, including most SRT8 models, SRT SUVs, and a number of RAM HD trucks.

In this guide, we’ll cover the 392 HEMI in detail, going over the engine’s specs, overall design, variants, common problems, and popular modifications.

Specs

| Engine | Chrysler 6.4L HEMI |

| Engine Family | Chrysler Gen III HEMI |

| Model Years | 2011-Present |

| Displacement | 6.4 Liters |

| Aspiration | Naturally Aspirated |

| Configuration | 90° V8 |

| Compression Ratio | 10.9:1 (Car) 10.0:1 (BGE) |

| Bore and Stroke | 4.09 in x 3.72 in |

| Valve Train | Overhead Valve, 16-valve (2 val/cyl) |

| Variable Valve Timing | Yes |

| Fuel System | Multipoint Fuel Injection |

| Head Material | Aluminum |

| Block Material | Cast Iron |

| Horsepower Output | 470-485 horsepower (Car) 366-410 horsepower (Truck) |

| Torque Output | 465-475 lb-ft (Car) 429 lb-ft (Truck) |

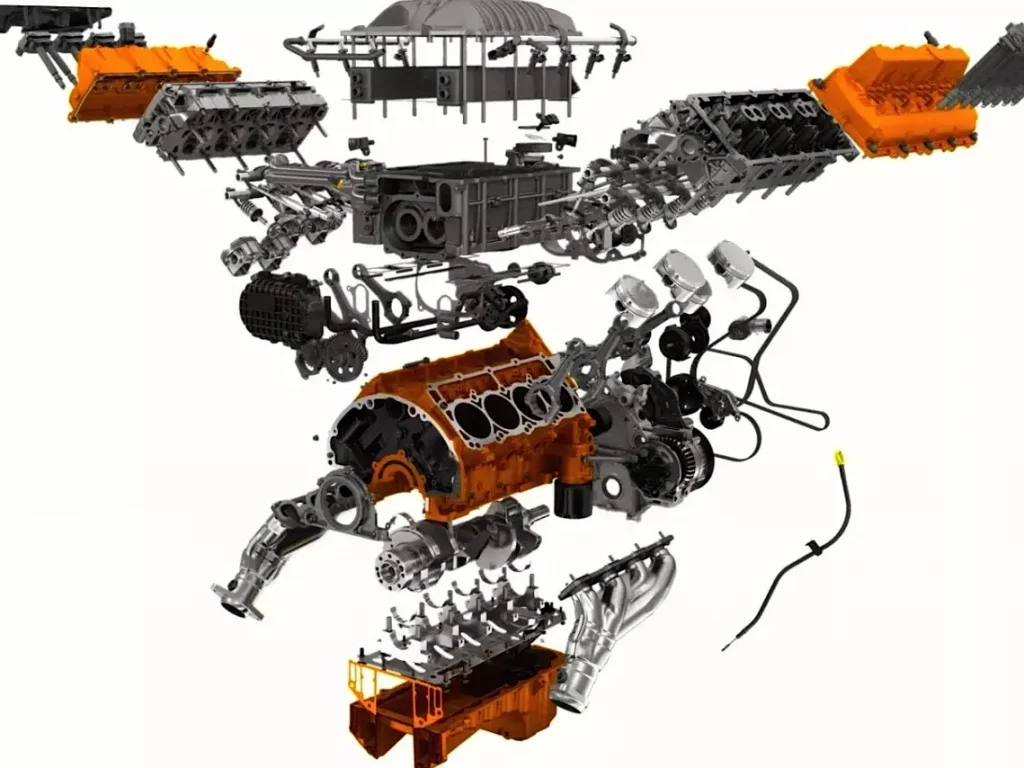

Design Basics

In terms of its overall design, Chrysler had no interest in breaking any molds with the 6.4 HEMI. As a result, it shared its construction with many of the engines that came before it. That is especially the case when you compare the 6.4L with the 6.1L HEMI that it replaced. However, there are differences to take into account, especially considering that the 6.4L came in both standard 392 form and a reinforced and stronger variant found in HEMI trucks called “Big Gas Engine” or “BGE” configuration.

While both engine variants feature cast iron block construction paired with aluminum twin-plug cylinder heads, the BGE engines feature thicker, reinforced, high nickel-content blocks with a shorter water jacket, making them extremely rigid and capable of withstanding massive amounts of power.

All 6.4L HEMIs are oversquare (or short-stroke) engines with a bore and stroke of 4.09 inches x 3.72 inches, making them revvy for a pushrod engine. The engine also features durable hypereutectic alluminum alloy pistons with a floating pin design. Keeping on the topic of the bottom end, it also features powdered metal I-beam connecting rod and a bulletproof forged steel crankshaft.

Compared to the previous 6.1L HEMI, the 6.4 featured an entirely revised cylinder head with new port and chamber designs and larger intake and exhaust valves. A new and more aggressive hydraulic camshaft with longer valves and valve springs conducted all of that. All 6.4L HEMIs use variable cam timing and engines equipped with automatic transmissions feature MDS cylinder deactivation technology which is not a fan-favorite, to say the least.

Variants

Since its release in 2005, a number of SRT/SRT8 vehicles have offered three different variants of the 6.4L HEMI. While the engines are relatively similar in terms of their overall construction, there are some significant differences between the engine variants that separate the higher-output variants from the lower-tier ones. You can easily distinguish the variants of the engine by the color of the block, along with the lettering on the engine itself and the casting numbers.

RAM MD and HD Variants

Compared to the standard 6.4L HEMI found in car and SUV applications, the 6.4L V8 found in RAM trucks is notably different. The MD (Medium Duty) variant, found in trucks like the RAM 2500 and 3500, and HD (Heavy Duty), found in trucks like the RAM 4500 and 5500, use different internal components, intake components, and other significant parts than the high-performance 392 variant.

The designers focused on towing capacity and bottom-end performance when creating both truck variants of the 392. As a result, they feature a stronger bottom end for the increased low-end torque. As I mentioned earlier, the BGE engines have reinforced high-nickel blocks built for abuse. The BGE 392 engines also have stronger and more robust high-grade T356 aluminum 356 cylinder heads. While the truck engines still use hypereutectic alluminum alloy pistons, they are a different design from the performance variant, lowering compression to 10.0:1. Unsurprisingly, the truck engines also received a revised camshaft more suited for low-RPM performance and torque.

Compared to the higher-performing car/SUV 392 variant, the truck variants also have more restrictive intake and exhaust manifold designs. The truck intake manifold is a completely different design, using a top feed-mounted throttle body. While the BGE 6.4L HEMIs aren’t the best performers out of the box, producing between 366 and 410 horsepower, they are still a good starting point for a 6.4L HEMI build.

Reliability and Common Problems

- MDS Failure/Lifter Roller Issues

- Broken Exhaust Manifold Bolts

The 6.4L HEMI has overwhelmingly positive reviews when it comes to reliability. Since the engine was so overbuilt and overengineered, there isn’t much room for anything to go seriously wrong. However, there have been some notable issues, primarily in the earlier years of the engine’s development, that some owners have experienced.

MDS Failure/Lifter Roller Issues

There is actually contention in the Chrysler community about the exact cause of the lifter issues in a number of HEMI engines, mainly the 5.7L and 6.4L. Most people claim that it is a manufacturer design flaw in the multi-displacement system and its associated lifters. The most common explanation for the 392 HEMI tick is a lack of lubrication to the lifters.

Obviously, like everything else in the engine bay, the 6.4L HEMI lifters rely on oil lubrication to prevent excess friction and wear. If the lifters aren’t supplied with effective oil to lubricate the contact point with the camshaft, damage can occur to both components. There are multiple reasons that the lifters might not be sufficiently lubricated. Since the 392 HEMI lifters are angled nearly horizontally, it is harder for oil to reach the needle bearings in the rollers themselves. If there is an insufficient amount of oil in the engine, due to an oil leak or oil loss, there might not be enough oil to lubricate the lifters.

If you don’t address the HEMI tick in a timely manner, the lifters can gather so much play that they no longer glide over the cam lobes like they are supposed to. Instead, the lifter’s play can allow the lifter ears to dig into the camshaft lobes. This grinds them down and changes the profile of the cam lobes themselves. If left for a long time, the lifters will eventually destroy the cam lobes entirely.

Broken Exhaust Manifold Bolts

While this problem might not be related to engine operation itself, it is still a very common issue on vehicles equipped with the 6.4L HEMI. It is also important to mention that broken/cracked exhaust manifold bolts are not a problem exclusive to HEMI engines. In fact, a ton of engines produced by Ford and GM are also prone to breaking over time. However, it does seem especially common on both the 345 and 392 HEMI.

The problem happens over time as the exhaust manifold continues to expand and contract as it repeatedly heats up and cools. Through that continued heat cycling, the bolts fastening the exhaust manifold to the exhaust ports wear out, eventually leading to the bolt heads snapping off. That’s seriously annoying, as it is a difficult thing to fix.

Weather is another factor that exacerbates the issue, especially if you live in an area with extreme climate changes. If you live in a snowy area, the heat cycling is more extreme, in addition to the added corrosion due to road salt.

Performance Mods

- Upgraded Camshaft

- Intake

- Tune

While there are other HEMI engines out there that are far better from an aftermarket performance perspective, there are still quite a few quality modifications available for the 392 HEMI. With that being said, it isn’t realistic to think that you’ll dramatically improve the performance of your HEMI without some pretty extensive modifications like forced induction.

Upgraded Camshaft

- 30-60+whp gains

- 20-40+wtq

- Awesome sounds

The right aftermarket cam can deliver insane 30-60+whp gains on the 6.4L HEMI. That’s about as good as it gets without adding even more expensive and complex mods – like a supercharger. Torque gains are also impressive with the right cam upgrades. Exact gains can vary and some cams may sacrifice low-end torque in favor of bigger top-end performance. Cams also sound amazing on the 392 HEMI, in our opinion.

It is important to mention that there are some pretty important considerations to take into account when it comes to picking the right upgraded camshaft for your 392. For one, it is critical to choose a cam based on the performance characteristics that you’re looking for. Do you want a low-end torque monster or a high-RPM drag strip screamer? Cams differ dramatically based on whether you have a BGE truck HEMI or a performance 392. Finally, you’ll have to install an MDS delete, as aftermarket performance cams don’t mesh with cylinder deactivation tech.

I won’t go into too much detail here about the specifics of picking the right camshaft for your build here, but we did write an entire article about the subject here if you are interested in learning more about camshaft grades for your 392.

Upgraded Headers

- 10-30+whp

- 10-30+wtq

- Louder, aggressive exhaust sounds

Headers (also known as the exhaust manifold) is a lengthy subject since there are so many different options. Long-tube, shorty, catless, and high-flow cats are just a few of the important header topics. However, we also wrote an in-depth 6.4 HEMI headers guide so be sure to check that out for all the details on header upgrades.

Headers offer some of the best power gains for the 6.4L V8 HEMI. If you’re looking to build a powerful 392, headers should definitely be towards the top of the mod list. The main goal with headers is to improve exhaust gas flow and reduce back pressure. Since the exhaust manifold bolts directly to the engine, it offers the biggest gains of any part of the exhaust system.

In addition to the impressive power and torque gains, it really wakes up the engine from a sound perspective, which is half of the fun anyway, right? Most HEMI owners opt for long tube headers, as they unquestionably provide the most significant performance gains. With that being said, there aren’t a ton of long-tube options for BGE 392s. It might be hard to source them if you have a RAM truck with the 6.4. Regardless, headers are one of the best performance mods for most naturally aspirated V8s, the 6.4L HEMI included.

Tune

- 5-15+whp

- Similar torque gains

- Bigger gains from additional mods

- Better throttle response

- Improved MPG

While tunes generally provide more notable performance gains on engines that use forced induction, they can still up the performance on the 6.4 too. It’s not just about the power gains from the tune alone. Tuning is also the foundation for maximizing power gains from additional mods. As you begin adding more air and fuel it’s important to properly tune the computer (PCM) to account for the changes.

On a bone stock 6.4L HEMI you may only see power gains around 5-15whp with tuning. There is only so much power a tuner can squeeze out of a NA engine. Torque gains should fall in the same ballpark and you’ll likely notice better throttle and engine response. Depending on the specific tune you may also see better fuel economy. However, if you’re using the newfound power then that likely won’t be the case.

You will need a tuner device to flash the PCM. A tuner will run in the ballpark of $400-600 and often include some basic off-the-shelf tunes. Ultimately, a tune is a great upgrade as it’s relatively inexpensive for power gains while also helping to improve performance from other upgrades.

The 6.4L HEMI is Both A Great Powerhouse and Workhorse

As an addition to the Gen III HEMI engine series, the 6.4L HEMI wasn’t an all-new engine or anything groundbreaking from a design perspective. However, that’s because the HEMI recipe had already been firmly tried and tested to everyone’s satisfaction. The additional displacement simply added some more potency to an already firebreathing formula, making it another solid performer in Chrysler’s stable.

The 6.4L was available in both high-performance vehicles, like the Dodge Challenger SRT8 and Charger, while also being versatile enough to power workhorse trucks like the RAM 2500, 3500, 4500, and 5500. If that doesn’t prove that the 6.4L is an all-star, I don’t know what would.

On top of being versatile, the 6.4L has very few serious problems to note. While lifter issues do affect the 6.4 in a similar way to the 5.7 that came two iterations before it, it is a relatively uncommon issue. Other than that, exhaust manifold bolt issues are the only other issue of note and that isn’t even an issue related to the engine’s design itself.

If you enjoyed this article and are looking for some more HEMI content, check out our 6.2L HEMI Hellcat Engine Guide, or our 426 HEMI Engine Guide if you’re looking for something more vintage.