How do superchargers work?

Meet Chandler

Chandler has a bachelors and masters degree in history as well as a passion for classics and muscle cars. His education and historical knowledge makes him skilled at crafting highly detailed articles about America’s muscle cars and automotive history. His love of muscle cars is undeniable, with him seeking them out at every opportunity during his visits to auto shows and car meets. Chandler’s knowledge and enthusiasm towards automotive history make him a great asset to the Muscle Car Club community.

How do superchargers work? It’s a question most have asked at least once at some point, usually after seeing a massive blower peeking out the hood of a 1960s muscle car. At first, superchargers – also referred to as blowers – might sound complicated. However, they actually operate under some pretty basic and easy to learn properties.

This article will explain everything you need to know about superchargers. We’ll cover their history, how they work, the different types, and we’ll end with a FAQ explaining how do superchargers work. Let’s get started.

How do superchargers work: What is a supercharger?

The most basic answer to “what is a supercharger?” is to call it a supplemental air pump for your engine. Superchargers work by artificially forcing extra air into an engine’s cylinders. This results in more horsepower and torque, making the car go faster (we’ll get into the technical details below). There are several different types of superchargers out there, as well as countless manufacturers of them.

Superchargers appear on both production cars and as aftermarket kits. Generally, blowers are reserved for high horsepower applications, and are usually fitted to larger displacement engines. There are both mechanical and electric superchargers, but for the most part mechanical ones are almost exclusively used in production vehicles.

The history of superchargers

Today, most people associate superchargers with internal combustion engines, but originally they were used for a different purpose. The first superchargers, known as roots-style, were invented and used in the mid-19th century. They were referred to as blowers and were used in the smelting industry to increase the heat in blast furnaces.

By the end of the 19th century, there had been several innovations on the original roots-style blower, and both the twin-screw and centrifugal styles were invented by the beginning of World War I. Starting during the war, people began to use superchargers on aircraft engines. In 1921, Mercedes debuted the first ever supercharged production car at the Berlin Automobile Exhibition.

Mercedes used superchargers in their early 6/25 and 10/40 hp models, which began production in 1922. In 1924, they began putting switchable superchargers on the 15/70/100 and 24/100/140 hp models. These were the roots style blowers and Mercedes fitted them to four-cylinder V-style engines. Mercedes squeezed as much as 38 horsepower out their 1.6 liter engine, and 65 horsepower out of the 2.6 liter engine. That might not sound like a lot today, but superchargers increased power by more than 50% on these engines.

Also in the 1920s was the Blower Bentley. This was a Bentley 4 1/2 litre with a roots-style supercharger on it, that produced as much as 240 horsepower — more than the naturally aspirated Bentley 6 1/2 litre. In the 1930s, Duesenberg slapped a supercharger on their Duesenberg Model SJ, where it produced a violent 320 horsepower. That decade also had the Auburn Speedster, which featured a blown 4.6 L straight-eight engine making 150 horsepower. Manufacturer Graham-Paige also made various supercharged coupes in the 1930s-’40s.

Modern supercharged era

By the 1950s, superchargers were becoming used more and more in performance racing. They were an easy way to boost power output for smaller displacement motors to give them big-displacement performance. McCulloch Motors created some of the first production superchargers under their Paxton Automotive brand. These superchargers were featured in iconic cars like the 1953 McCulloch Corvette Supercharged, various Kaiser-Frazer models of the 1950s, and 1957 Ford Thunderbird.

The 1954 Kaiser Manhattan was the first post-WWII production vehicle to be fitted with a supercharger. The McCulloch Corvette was an experimental model, and was not fitted with a blower from the factory. In 1957, Ford put a centrifugal style blower as an option for the 312 cid V8 in the T-Bird.

From the late-’50s to early-’60s, Studebaker-Packard produced a number of models with superchargers fitted to them. These included the Studebaker Golden Hawk and Packard Hawk, two of the most iconic looking muscle cars of all time.

During the early years of muscle cars, in the ‘50s and ‘60s, enthusiasts commonly put on aftermarket superchargers looking to increase the power of their big block V8s. One of the most famous supercharged muscle cars was the blown Carroll Shelby 427 Cobra Super Snake, which actually featured dual paxton superchargers for the best response.

Since the 1960s, superchargers have been fitted to various different production models, usually as an optional upgrade. Some of the most popular modern cars with superchargers fitted from the factory are the Cadillac CT5-V Blackwing, Chevrolet Camaro ZL1, Dodge Challenger/Charger SRT Hellcats, Ford Shelby GT500, and Jaguar F-Type.

Aftermarket supercharger popularity

However, while various production vehicles have been fitted with blowers, their iconic reputation has largely come from racing applications. Since the 1950s, superchargers have been a common aftermarket upgrade for those looking for a little more sauce than the factory provided. By now, many performance cars have specific supercharger kits designed for them by aftermarket companies. Pretty much any modern muscle car probably has a compatible blower kit already available.

How do superchargers work

Now that we know a little bit about their history, let’s look at the science behind how superchargers work. When trying to make the most amount of horsepower and torque, the goal is to get as much air and fuel into and out of the engine as quickly as possible. Adding a supercharger is generally referred to as “forced induction,” as you’ll see below.

Normally, engines can hold as much air as their displacement, meaning that a 400 cid engine can displace 400 cid of air. However, usually naturally aspirated engines will not hit 100% volumetric efficiency. Volumetric efficiency is a measure of how much air is actually being displaced vs how much is possible.

The purpose of a supercharger is to increase volumetric efficiency by forcing more air in than the engine takes in naturally. Hence the term “forced induction.” Forcing in more air allows for more fuel to be burned, which results in greater torque and horsepower. The more air the more potential power, hence the want for bigger and better superchargers.

There are a few different methods for forcing the extra air into the cylinders, as we’ll discuss below, but those are the basic principles. Supercharger = greater volumetric efficiency = more torque and horsepower.

Supercharger system components

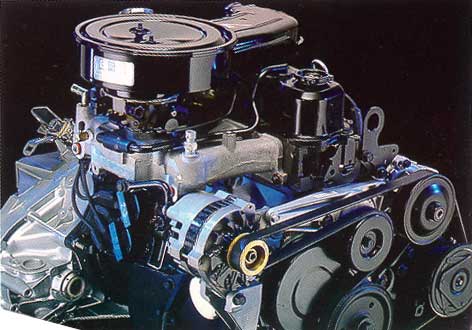

While they are not all the same, most superchargers have similar components. First is going to be an intake system. Most superchargers use cone style intakes that directly connect to the supercharger intake. You might also see the iconic injector hat systems, which are essentially open throttle bodies that feed air and fuel directly into the supercharger intake. Injector hats are used almost exclusively in drag racing applications.

After air makes its way into the supercharger, depending on the type, it will either get compressed or pushed directly into the engine. Some supercharger systems have intercoolers or heat exchangers, which help reduce the temperature of the air going into the engine. Colder air means more power, so intercoolers can be very important parts of the system.

What is boost?

If you have spent any time around supercharged vehicles, you have undoubtedly heard the term boost. But what does it mean? Boost is simply the name for the extra air that is getting pushed into the engine by the supercharger. Usually, in the U.S., we measure boost by PSI or BAR, with PSI being the most standardized.

Your typical supercharger system will run anywhere from 5-15 PSI of boost. It’s possible to run more boost, but as you’ll see below, most people opt for turbochargers for high boost applications. Some supercharger styles are also better for running higher amounts of boost than others.

How do superchargers work: The three types of superchargers

There are several different types of superchargers, but by far the most used in the automotive world are Roots, Twin-screw, and Centrifugal style blowers. Roots and twin-screw blowers look relatively similar to each other, whereas centrifugal blowers look like turbochargers. All three have been used in production vehicles, with roots style being the most traditional.

The three superchargers can be broken down into two kinds, positive displacement and dynamic displacement. Positive displacement superchargers produce a constant amount of boost pressure, whereas dynamic superchargers produce different levels of boost at different RPMs. Dynamic superchargers are best for running high boost.

How do superchargers work: Roots Superchargers explained

Roots superchargers are somewhat known as the old school type of blower. These are usually the ones you see in drag racers poking through the hood, as they sit directly on top of the engine. Their design is pretty simple. Roots blowers are belt driven and consist of two rotors put close together, but not touching. When the supercharger operates, the two rotors spin at the same time, forcing air to travel around them and into the engine.

Importantly, roots superchargers do not compress air themselves. Rather, they push air through into the engine where it then gets compressed. Roots superchargers are the most basic style of superchargers, and are thus the cheapest and most widely used. Roots superchargers are positive displacement, so they produce a constant amount of boost.

Some of the most well known roots superchargers are the blowers used on Detroit Diesel engines. As well as the Eaton TVS blowers used on cars like the Shelby GT500 and C7 Corvette.

How do superchargers work: Twin-Screw Superchargers explained

Next on our list are twin-screw superchargers. Twin-screws work very similarly to roots superchargers and are also belt driven, but have one important difference. Twin-screws compress the air before sending it into the engine. This makes them much more efficient, but also much more expensive and more complicated. Twin-screws are positive displacement blowers.

Twin-screws have a similar twin-rotor setup, but the design is different and has much tighter clearances. The rotors mesh with each other, and as air is drawn in they progressively compress it before it passes through. They look very similar to roots style blowers and also sit on top of the engine, and can often be seen sticking through hoods as well.

Some of the most well known twin-screw superchargers are made by whipple, one of the biggest supercharger manufacturers in the world.

How do superchargers work: Centrifugal Superchargers explained

The final type of supercharger we’re going to cover are centrifugal style superchargers. Centrifugal superchargers sit alongside the engine instead of on top of it. Whereas both roots and twin-screw blowers replace the intake manifold, centrifugal blowers use a traditional throttle body to intake manifold setup, just like a naturally aspirated system.

Centrifugal superchargers have very similar designs to turbochargers, except they are belt driven instead of exhaust gas driven. They have an internal impeller and operate at much higher speeds than roots or twin-screws. They are belt driven and have dynamic displacement, and the faster the belt spins the more boost is created.

Centrifugal blowers are best suited for high boost applications, as they require less energy to make more boost pressure. This is due to the internal impeller, which runs much faster than rotors. Due to their setup, centrifugal blowers are easier to set up with intercoolers and heat exchangers. They are not mounted on top of the engine and have piping connecting them to the throttle body. This makes them perfect for adding in intercoolers to decrease the temperature of the boost.

Some of the most well known centrifugal style superchargers are the ProCharger and Vortech proprietary supercharger systems.

How do superchargers work: Supercharger vs Turbocharger

You’re probably asking yourself, which is better, a supercharger or a turbocharger? The answer depends on your setup, engine, and power goals. Typically, superchargers are easier systems to bolt-on to an engine and simpler to tune and maintain. Turbochargers require a lot more work and fabrication, but they are also more efficient.

If you are looking for the quickest response with the most low-end power, superchargers are usually the best options. Roots and twin-screw blowers are capable of providing an instant jump in power, though centrifugals do take a little longer.

The reason superchargers are better for instant response is that they are belt driven. Turbochargers require exhaust gasses to power their impeller, which means they can lag at lower RPM. Superchargers are run on belts, so they can provide good response at lower RPM when the exhaust isn’t sufficient to power a turbo to full boost.

However, if you’re looking for the most possible power from your forced induction system, you will definitely want to go with a turbocharger. Since superchargers are belt driven, there is always some parasitic loss between the belt and the blower. As a result, superchargers cannot make the same amount of boost as turbochargers.

Turbochargers rely on exhaust gasses to power their impellers. Turbos can run as much as 40-50 PSI of boost, whereas superchargers are limited to about 15 PSI. Even centrifugal superchargers struggle to keep up with turbos because of the limits of their belt drive. There is a trade-off, though. The bigger the turbo the more boost it will make, but that also increases lag. Typically, even the highest PSI centrifugal blowers still get pretty good low-RPM response compared with a turbo.

How do superchargers work: Supercharger FAQ

How old are superchargers?

- Superchargers were first invented in the 19th century, but did not become used in production vehicles with internal combustion engines until the 1920s. They have been sporadically used by manufacturers on cars since then, and are primarily used in aftermarket kits by racing enthusiasts.

What was the first production car to use a supercharger?

- The first production car to use a supercharger was the Mercedes 6/25 hp back in the 1920s. It debuted at the Berlin Automobile exhibition in 1921 and was put in production the following year.

What are the different kinds of superchargers?

- The three main kinds are superchargers roots, twin-screw, and centrifugal. Both roots and twin-screw use rotors to create boost and are positive displacement, meaning they produce a constant amount of boost. Centrifugal blowers use an impeller to create boost and are dynamic displacement, meaning they produce different amounts of boost depending on the speed of the belt drive.

Will a supercharger blow up my engine?

- It depends, but most engines cannot handle the increased power that a supercharger will bring. Most engines will break internal pieces like rods and pistons after just a few PSI of boost. With that being said, many engines can easily take supercharging and they are a great mod for extra power. Some of the best engines for supercharging are big block V8s, the GM/Chevy LS-engine series, and the Ford modular engine series.

How much does a supercharger cost?

- This depends on the system, but most supercharger builds will set you back at least $10,000 when all is said and done. Most systems are between $3,000 – $7,000, depending on blower size, style, quality, and optional components. After that, most engines will need a few thousand put into the fueling and exhaust systems to make them compatible. You’ll also need to factor in labor if you can’t install the supercharger yourself.

What modern cars use a supercharger?

- There are many modern cars that use a supercharger. Some of the most notable current models with a supercharger are the Cadillac CT5-V Blackwing, Chevrolet Camaro ZL1, Dodge Challenger/Charger SRT Hellcats, Ford Shelby GT500, and Jaguar F-Type. The C7 Corvette Z06 also had a supercharger on it, though the C8 does not.

Which is better, superchargers or turbochargers?

- It depends on your power goals and engine size. Superchargers are better for largely displacement engines, because of the power needed to operate the belt drive. Superchargers are also better for quick response and low-end torque. If you want the highest horsepower, turbochargers are the best option, though you do sacrifice lag.

Can I supercharge any engine?

- Technically, you can supercharger pretty much any engine. However, as we mentioned, most engines cannot handle the increased power of a supercharger. If in doubt, consult a professional tuning shop and explain to them your power goals and see if a blower is the right solution for your build.